You’ve likely come across the term Phase Change Materials (PCM) and wondered, “What exactly are PCM, and why is there such a push for them as a sustainable solution?” Let’s explore the essence of PCM—they are substances with the unique capability to absorb or release energy during a phase transition. This exceptional quality enables PCMs to smoothly shift between solid and liquid states, effectively storing and releasing thermal energy in the process.

How Does It Work

When you heat a solid PCM, it turns into a liquid, absorbing a lot of heat energy in the process. Similarly, when you cool a liquid PCM, it turns into a solid, releasing the stored heat energy. This ability to absorb and release heat without changing its temperature is what makes PCM so special.

Let’s consider an everyday example: ice turning into water. To melt ice, it requires a considerable amount of energy (334 joules per gram, to be precise). However, once it becomes water, it only needs 4.18 joules per gram to raise its temperature by one degree Celsius. This stark contrast illustrates the unique capability of PCMs in absorbing and releasing energy.

Types of Phase Change Materials

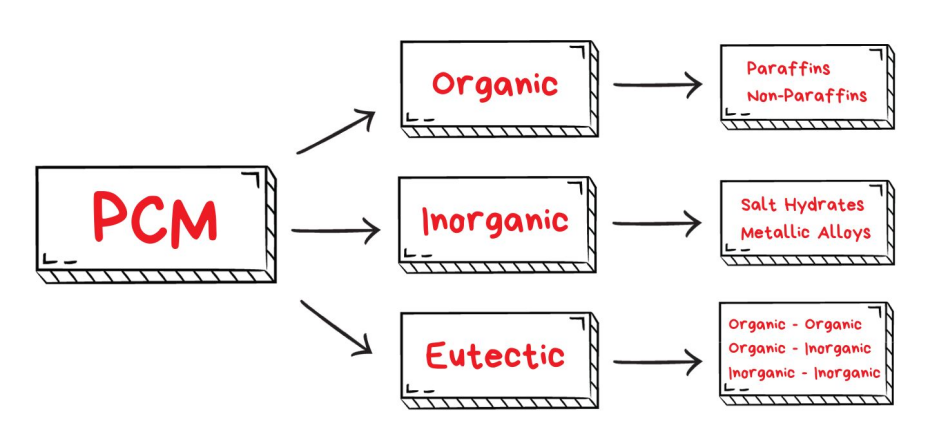

Phase Change Materials can be categorized into three main types: Organic, Inorganic, and Eutectic.

Organic PCMs: Organic PCMs are made from paraffin and non-paraffin materials, such as petroleum, plants, or animals. Paraffin wax is a notable example. These PCMs are preferred for their low cost, chemical stability, and ease of availability.

Inorganic PCMs: Inorganic PCMs like metallic alloys and salt hydrates utilize minerals and natural salts, providing high latent heat capacity and thermal conductivity, making them ideal for various applications.

Eutectic Mixtures: Eutectic PCMs are innovative blends of different materials, carefully designed to achieve specific melting points and optimize energy storage capabilities.

Sustainability of PCM

Phase Change Materials (PCMs) are considered sustainable due to their ability to enhance energy efficiency, reduce overall energy consumption, and integrate with renewable energy sources. They contribute to a more stable and reliable energy supply, extend the lifespan of products, and often involve non-toxic and environmentally friendly materials. The adaptability of PCMs in various applications makes them versatile tools for improving sustainability and minimizing environmental impact.

Applications and Impact

Phase Change Materials find diverse applications, with the following examples representing just a few available options that Pluss Advanced Technologies has to offer.

Medical Sector: PCM-based products are utilized in the healthcare field for temperature-controlled shipping of medications, vaccines, and other sensitive medical supplies. Maintaining the required temperature ensures the efficacy and safety of these products during transit.

Energy-efficient Buildings: PCM-enabled building materials regulate indoor temperatures by absorbing the excess heat during the day, releasing it at night, and vice versa. This strategic thermal management minimizes the reliance on continuous heating or cooling, resulting in substantial energy savings.

Transportation: Phase Change Material (PCM) technology finds application in cold chain logistics, especially in passive refrigerated vehicles, maintaining the right temperature for perishables. By minimizing the dependency on active cooling during transport, PCMs enhance energy efficiency and environmental sustainability in the transportation of perishable goods.

Solar Energy Solutions: In the realm of renewable energy, PCMs play a pivotal role. They are integrated into solar water heaters, largely increasing their storage capacity, ensuring a steady supply of hot water even when the sun is not shining.

Challenges and Future Innovations

While Phase Change Material technology has made remarkable strides, challenges such as material cost, encapsulation techniques, and durability persist.

Researchers and scientists around the world are tirelessly working on overcoming these hurdles, envisioning a future where PCM applications become even more widespread and impactful.

Transforming the Future with Phase Change Materials

From enhancing the energy efficiency of our homes to paving the way for greener transportation solutions, PCMs are at the heart of a sustainable future. With continued research and innovation, these materials will undoubtedly shape a world where energy conservation meets unparalleled efficiency, ensuring a brighter, eco-friendly tomorrow for generations to come.

Glacier Coolant Technology (Beijing) Co., LTD. Related products:

phase change refrigerant:

LM-XL-1

LM-XL-2

LM-XL-3

LM-XL-4/p>

phase change heat storage agent:

LM-XR-1

LM-XR-2

LM-XR-3