Use of Glacier Coolant in Cultivation of Needle Mushroom

There is a great market demand on needle mushroom in China, which is of high nutrition. The conditions of cultivation need be carefully controlled, to which the quality of mushroom can be really sensitive. Industrial cultivation of needle mushroom has become more and more popular in China with precise control of its growing conditions, ensuring the production level with satisfying quality. Glacier coolant has been utilized in many refrigeration systems for cultivation of needle mushroom.

The main production flow of needle mushroom is: Cultivation of raw material – Sterilization by steam – Cooling – Inoculation – Budding -Forcing – Germination – Adaption – Maturation – Package – Out of stock. It requires different humidity and ventilation level at individual stage. The refrigeration system must deliver the right temperature, humidity and amount of air. The detailed requirements are listed in Table-1:

At the moment, small capacity refrigeration systems for cultivation of needle mushroom deploy direct refrigeration system which consists of compressor, air condenser, air cooler and expansion control valve. There are some manufactures utilizing refrigerated storage system. Although direct air coolers have high heat capacity, the distance between fins is quite small (2~2.8mm). Frost forms on the surfaces of fins blocking the gaps between them, resulting in loss or even no heat transfer of cooling circuits. Due to the fire-proofing nature of insulation material, only natural deforest is allowed, which is time consuming. Mushroom’s quality is also reduced by variation of refrigerated storage system’s temperature. Utilization of Glacier Coolant as secondary refrigerant for large capacity refrigeration systems are strongly recommended. The refrigerated storage system is stable with temperature variation within 0.5℃. The refrigeration system consists of primary refrigeration system including screw compressor, evaporative condenser、secondary refrigerant pump、buffer station、indirect air cooler and weighted percentage motorized control valve.

Glacier Coolant Refrigeration system is selected for a project which produces 160 ton/day needle mushroom. Based on the operating temperature of each room, we proposed the solution of providing two coolant streams: -5℃ for product storage (0-4℃) and maturation room (4-6℃); 3℃ for cooling room, incubation room, inoculation room and package room. There are multiple primary refrigeration systems and corresponding evaporative condensers which can be standby system for one or another. No redundant fans are required. The whole site is segmented and each segment is installed with two variable speed pumps which adjust the coolant flow rate depending on demand. Heat recovered from the primary refrigeration system is used for defrost as well as heat input required for incubation room. The production site is located in Northern China and the load capacity can be adjusted by switching on/off systems based on ambient temperature during winter, minimizing the power consumption. The Glacier Coolant type is LM-4, featuring great heat capacity and low viscosity at operating temperature. The system is highly energy efficient and there is no flashing point for the coolant, eliminating risk of fire. The coolant is highly anti-corrosive, much lowering the deterioration rate of the equipment and saving maintenance cost during production life.

Refrigeration systems utilizing Glacier Coolant designed for cultivation of needle mushroom provide high level of automation and can be delivered in completed assembly. It is energy efficient, requires minimum level of maintenance and can be applied to large scale of industrial production.

Effect of coolant cycle specific heat and density

In the coolant application system, the system is usually determined in the design stage. In the later stage, It is necessary to replace the coolant with different physical properties of the system. there will be some mismatches, and the final result is the reduction of energy efficiency.from the perspective of heat transfer and fluid, It is found that the specific heat and density have a great impact on the system.

The specific heat usually refers to the heat required for 1kg homogeneous material to increase by 1K without phase change and chemical change. Generally, this value will decrease with the decrease of temperature. this parameter is usually used in design calculation, and the density of coolant is calculated jointly with this parameter. it is one-sided to comment on the quality of the coolant by talking about a specific heat.

The specific heat can be combined with the density to calculate the circulating volume of the system. From the perspective of fluid, the circulating volume is directly related to the circulating energy consumption of the coolant. The pump power can be determined by combining the viscosity and flow rate of the coolant. Another is to determine the material and pipe diameter of the circulating system pipeline and its impact on the initial investment of the system. From the perspective of heat transfer, under the unit circulating volume, the larger the volume specific heat is, the greater the heat exchange is, which is more beneficial to the circulation of the system. The efficiency of the heat exchanger is different according to the parameters of the heat exchanger,ε=(t2-t1)/(T1-t1),或ε=(T2-T1)/(T1-t1).With large volume specific heat, the available temperature difference of T2-T1 will increase, and the heat exchange efficiency ε will improve.

Obtaining a higher volume specific heat can improve the fluid heat transfer efficiency, but it also needs to be combined with the thermal conductivity, kinematic viscosity and Pr number of the coolant. The comprehensive efficiency of these parameters is to finally determine which coolant is more suitable. Glacier Coolant provides professional coolant and professional coolant system scheme for customers.

Application of Glacier Coolant in Cold Storage

For the cold storage system, a shell and tube heat exchanger, a set of circulating pump unit and a set of water supply and constant pressure device are designed in the refrigeration plant room.Through shell and tube heat exchanger and fluorine in the direct refrigeration system for heat exchange, through the circulation pump group of continuous pressure transmission, so that the cold storage special coolant in the system continuous circulation. The specific workflow of the system is:The LM-4 Glacier Coolant in the system exchanges heat with low-temperature fluorine in the plate heat exchanger, reduce the temperature of the special coolant for the cold storage, and then through the pump unit of the special coolant system for the cold storage, the LM-4 coolant reaching – 30 ℃ is sent to the cold storage for heat exchange , absorb the heat of the cooled goods in the cold storage and maintain the storage temperature at – 18 ℃, The temperature of the coolant increases to -25℃ after absorbing the heat,and returns to the shell and tube heat exchanger in the refrigeration plant room through the pipeline for heat exchange, and the low temperature fluorine is cooled again.

Through the continuous circulation of the coolant solution in the system, the heat is brought back to the refrigeration plant room, and the heat is discharged outdoors through the phase change heat exchange of Freon. The temperature in the cold storage is to maintain the temperature required by the goods, so as to achieve the best environment for preserving the goods.

According to the actual situation of the old cold storage, the system fully considers the specific historical conditions and the existing operation status of the cold storage.The scheme of replacing only the refrigerating machine, the main pipeline of the system and the medium flowing in the pipeline without changing the enclosure structure and pipe arrangement of the existing cold storage .According to the requirements of the scheme, the main pipeline from the cold storage to the the refrigeration plant room is rearranged, and the newly arranged main pipeline is connected with the evaporator in the cold storage to form a closed loop of the coolant system. Change the transmission medium in the system from ammonia to LM-4 Glacier Coolant.

After the transformation, the system operates well. Through data observation, the refrigeration system of the cold row pipe cold storage fully meets the temperature requirements of the goods in the cold storage, but the temperature of the two cooling fans cold storage can only be maintained at -12℃. At present, these two cold storage are mainly used as ice storage.The specific reason is that the clooant of the heat exchange efficiency of the cooling fan is lower than that of the pipe, so it is necessary to appropriately increase the end heat exchange equipment and meet the requirements. Therefore, the practical application of refrigeration system conversion cooling system is feasible.According to the actual operation of special coolant for Glacier Coolant, the advantages of using coolant are summarized as follows:The direct refrigerant system is gathered in the refrigeration plant room, facilitating the manufacturing, installation, operation and management of overall system ,and improves the refrigeration efficiency.Reduce the refrigerant charge in the direct refrigeration system, reduce the pipeline layout area of the direct refrigeration system and reduce the leakage coefficient.The use of coolant system can facilitate the transmission of cooling capacity and the distribution and control of cooling capacity.The temperature control in the cold storage is more accurate, the temperature fluctuation is small, and the refrigeration quality of food is improved.

The new special coolant for cold storage has more advantages and application cases, and has better application prospects.

Glacier Coolant: The Best Option of Heat Transfer Media for API and Intermediate Processing

In API and intermediate manufacturing industries, chemical synthesis takes place in reactors where normally requiring heating or cooling to facilitate the yield. Heat transfer media exchanges heat with reactants in jacket of reactors. Disadvantages of using primary refrigeration include safety and explosion risks (e.g. Ammonia) and environmental concerns (e.g. HCFC has high global warming potential). Use of freon us also not cost competitive especially in scenario of API manufacturing. CO2 involves high pressure operation, which is not suitable for batch process due to the instability of compressor for short period operation. It requires high purity of primary refrigerant (>99.5%) in close loop systems, which is a huge challenge for API manufacturing. Both low and high temperature operations can be required in chemical synthesis, leading to change over of primary refrigerant which further increases the system complexity. Therefore, secondary refrigeration is the best choice for API synthesis.

Common secondary refrigerants include glycol, brine, water and heating oil. One of the key issues for secondary refrigerant is corrosion, which can cause leakage and even equipment damage. Switching between low and high temperature heat transfer media might result in residue left in the system, impacting heat transfer performance and system operation.

Glacier coolant, our patented engineered heat transfer fluid, can either be utilized as low or high heat transfer media, with high anti-corrosion property and avoid the necessity of heat transfer media switching. It is the perfect choice for API and intermediate manufacturing.

Comparison between Ammonia+CO2 integrated refrigeration system and Glacier Coolant refrigeration system

1. Safety

Ammonia as primary refrigerant is toxic, flammable and explosive. CO2 which is the secondary refrigerant operates at pressure five times higher than Glacier Coolant. The Glacier coolant secondary refrigeration system runs at almost ambient pressure and the pump is only designed for overcoming system hydraulic loss.

Due to the characteristics of ammonia, the project can be identified as high hazardous project and requires frequent round checks. The pipework of CO2 needs to be designed to withstand high pressure (GC2 grade) and be closely monored as well. Glacier Coolant refrigeration system is not required to comply with such regulations due to its safe characteristics.

2. Cost

The equipment cost of ammonia+CO2 refrigeration system is 10% higher than that of Glacier Coolant refrigeration system. Ammonia and CO2 system requires dedicated compressor. For CO2 system, higher pressure head is required than that of ammonia or Freon compressor. Subsequently, higher pressure grading is required for its auxiliary systems such as pipes and valves.

As Glacier Coolant refrigeration systems operates at much lower pressure, it saves significant equipment cost. Standard pipes and valves can be selected. Apart from equipment cost, ammonia system also requires safety measures of fencing wall and impoundment. The coexisting of ammonia and CO2 systems requires dedicated ventilation systems due to their different density, adding further cost of ammonia+CO2 refrigeration system.

3. Operation conditions

Phase transition take place in both ammonia and CO2 refrigeration systems at uncontrolled rate resulting in temperature fluctuation. It requires more complicated process control system and instrumentation, which further increases cost. Intensive training of labor is also required.

If there is a fire incident, both ammonia and CO2 need to be discharged in a safe way. Regular training is pivotal and mandatory. The system cannot be shut down for long period of time otherwise the pressure of CO2 will continue to increase in the system. It is also not energy efficient to run CO2 system at low demand of cooling.

Diagram of indirect refrigeration optimization scheme of cold storage

The Glacier Coolant refrigeration system works together with primary refrigerant of Freon and it utilizes sensible heat. It stabilizes the system and the automation is simple. The temperature of coolant is controlled by varying flow rate which is driven by the compressor. Under emergency situation, Glacier Coolant can be remained in the system as long as needed, without concerns of over- pressurization, even during long term shut down.

Application of Fluorinated Liquid in Data Processing Centers

The rapid growth of cloud technology, edge computing, large scale internet of things and AI has increased the demand of data processing centers significantly. There is ever more challenging requirements of capacity and energy efficiency for data processing centers, along with growing number of IT equipment and servers. It is projected that air cooling will no longer be able to cope with stringent requirement of future national standard energy efficiency. Liquid cooling will dominate the market for data processing centers and the selection of cooling media is pivotal.

In response to the current trend, the research team of Glacier Coolant developed the modified fluorinated liquid coolant, targeting systems demanding high efficiency cooling such as data processing centers, heating elements and electrical chips. Modified Glacier Fluorinated Liquid is transparent, tasteless, non-toxic, safe and un-dissoluble in water. It is thermally stable and environmentally friendly.

The boiling point of Modified Glacier Fluorinated Liquid is moderate and (~50℃) and the latent heat is around 121.7 kJ/kg. By evaporating fluorinated liquid coolant which immerses data processing centers, the heat is taken away from the facilities. It eliminates the use of air conditioning and the energy efficiency is really high. The power usage effectiveness (PUE) is below 1.1, saving more than 85% power consumption compared to air conditioning. It also has very high insulation property against electric conduction. Its dielectric strength up to 55 kV and therefore it will not damage electrical instrumentation. It is chemically inert with no ignition and flashing points, non-combustible and non-explosive. Modified Glacier Fluorinated Liquid gas excellent thermal conductivity, good flowability and system compatibility. The Ozone Depletion Potential is 0 and the global warming potential is 7 making it suitable for many applications. Apart from data processing center, it is also applied in power inverter for high speed rails, hydrogen fuel cell and electrical battery vehicles, semi-conductor equipment cooling, wind power, nuclear, ultra-high voltage power gird and military radar systems.

A well-known research institution conducted a few measurements on Modified Glacier Fluorinated Liquid in our R&D center in April, 2021 and the results were illustrated in the table in below. All the figures meet the requirements for use.

Table.1 Physical properties of Modified Glacier Fluorinated Liquid

As shown in Figure.1, CPU are placed in the cooling box of fluorinated liquid immersion cooling system where heat of elements of CPU is dissipated. When servers are in operation, heat generated by the server’s elements boils fluorinated liquid due to its low boiling point. The evaporated coolant is condensed when it contacts with tubes of condenser located above CPU. The condensed fluorinated liquid is re-utilized, continuously cooling CPU elements.

Figure.1 Process Flow Diagram of Fluorinated Liquid Immersion Cooling System for Data Processing Center

It saves more than 85% of power consumption by making direct contact between the elements of data processing system and Modified Glacier Fluorinated Liquid to achieve effective cooling. The system configuration is simple, enabling compact server assembly, which saves space. The water and coolant consumption is relatively low with only internal recirculation, saving significant OPEX.

CPhI & P-MEC China 2020has come to a successful conclusion!

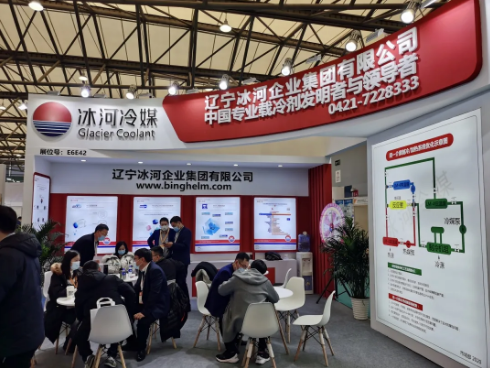

Glacier exhibition site

(Exhibitor glacier coolant)

Glacier coolant and colleagues from all walks of life have worked together to overcome difficulties and forge ahead in this unusual year. Let’s review the unique style of glacier coolant in this CPHI.

Glacier exhibition review

(Fan Dongmei, executive vice president of glacier coolant, introduced the company’s products to visitors)

(There was an endless stream of visitors in front of the glacier coolant booth)

(Visitors come to learn about glacier coolant)

(Leave contact information for each other for in-depth understanding after the meeting)

In this exhibition, glacier coolant not only provides one-to-one answer service, but also allows visitors to deeply understand and trust glacier coolant.

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, it solves the three major problems of traditional refrigerant “corroding equipment, low efficiency and polluting the environment”, and prolongs the service life of refrigeration equipment by more than twice.

The company has more than 2000 stable customers in the pharmaceutical industry, chemical industry, refrigeration industry, food industry and scientific research institutes.

2020 is coming to an end. Thank you for your support and love to binghe. We will continue to uphold the belief of “taking customers as our home, enterprises as our home and binghe as our pride” and continue to provide customers with professional and high-quality products. Remember the original heart, move forward firmly, and look forward to your next encounter!

Congratulate! 2020 China po-ppg-pu industrial chain high quality development forum was successfully held in Zibo!

In recent years, Zibo has vigorously implemented the “top four” industrial climbing plan of new materials, intelligent equipment, new medicine and electronic information, and initially formed four advantageous industrial clusters of fluorosilicone materials, polyurethane, polyolefin and engineering plastics. New chemical materials have developed into one of the core competitive industries in Zibo.

On December 16, the third China Zibo International Conference on new chemical materials industry was grandly opened in Zibo Convention and Exhibition Center. The industrial conference was hosted by China fluorosilicone organic materials industry association, Huantai County People’s government and China Epoxy Resin Industry Association (Preparatory), organized by Beijing fluorosilicone Technology Development Co., Ltd., Beijing Sinochem new materials technology center, Dongyue fluorosilicone Technology Group Co., Ltd. and Zhejiang Lingzhi new materials Co., Ltd., and organized by China Petroleum and Chemical Industry Federation, Zibo Municipal People’s government, China Polyurethane Industry Association Supported by China Membrane Industry Association, the event will take place from December 16 to 18.

Song Xianzhu, Secretary of the Party committee and vice president of China Electronic Information Industry Development Research Institute, Cao Xianjun, vice chairman and Secretary General of China fluorosilicone organic materials industry association, Xu Dingming, counsellor of the State Council and former director of the Energy Bureau of the national development and Reform Commission, Liu Weiping, deputy chief Engineer of Shanghai Aircraft Manufacturing Co., Ltd. of China Commercial Aircraft Corporation, and LV Guoguo, Secretary General of China Polyurethane Industry Association, Xie Hongliang, Deputy Secretary General of China epoxy resin Association, attended the opening ceremony; Ma Xiaolei, deputy secretary of Zibo Municipal Party committee and acting mayor, attended the opening ceremony and delivered a speech; The ceremony was presided over by song Zhenbo, member of the Standing Committee of the municipal Party committee and vice mayor, and attended by Zong Zhijian, Secretary General of the municipal government.

Ma Xiaolei, deputy secretary of Zibo Municipal Party committee and acting mayor, delivered a speech

Song Zhenbo, member of the Standing Committee of Zibo Municipal Party committee and vice mayor, presided over the meeting

Speech by Cao Xianjun, vice president and Secretary General of China fluorosilicone Organic Materials Industry Association

Speech by Xie Hongliang, Deputy Secretary General of China Epoxy Resin Industry Association

Jia Gang, Secretary of Huantai County Party committee, attended the opening ceremony

Bian Jiangfeng, deputy secretary of Huantai County Party committee and head of Huantai County, attended the opening ceremony

From December 17 to 18, the “2020 China po-ppg-pu industrial chain high quality development forum” was successfully held in Zibo, Shandong Province, supported by Zibo Municipal People’s government, hosted by China Polyurethane Industry Association and Huantai County People’s government, jointly organized by polyol Professional Committee of China Polyurethane Industry Association and Beijing Sinochem new material technology center, and co organized by Suzhou antway Valve Co., Ltd!

Experts and representatives from nearly 100 units in the upstream and downstream production enterprises, technical research units, new product development institutions, supporting equipment enterprises and financial investment institutions of propylene oxide (PO) – polyether polyol (PPG) – polyurethane (PU) industrial chain from all over the country attended the meeting.

First of all, LV Guoyang, Secretary General of China Polyurethane Industry Association, and Liu Yi, chairman of Shandong Bluestar Dongda Co., Ltd., respectively delivered welcoming speeches to the meeting and extended a warm welcome to all experts, scholars, backbone and colleagues of the enterprise.

LV Guoyang, Secretary General of China Polyurethane Industry Association

Liu Yi, chairman of Shandong Bluestar Dongda Co., Ltd

Special report

On the morning of December 17, the meeting was presided over by Guo Hui, chief engineer and assistant general manager of Shandong Bluestar Dongda Co., Ltd.

Guo Hui, chief engineer and assistant general manager of Shandong Bluestar Dongda Co., Ltd

Li Jianbo, Deputy Secretary General of China Polyurethane Industry Association

Li Jianbo, Deputy Secretary General of China Polyurethane Industry Association, made a report entitled “impact of national safety and environmental protection policies on the development of po-ppg-pu industrial chain”.

Yu Chunmei, deputy chief engineer of PetroChina Jilin Chemical Engineering Co., Ltd

Yu Chunmei, deputy chief engineer of PetroChina Jilin Chemical Engineering Co., Ltd., made a keynote report entitled “analysis of propylene oxide industry development trend and investment opportunities”.

Ma Huiling, deputy general manager of Shandong Bluestar Dongda Co., Ltd

Ma Huiling, deputy general manager of Shandong Bluestar Dongda Co., Ltd., made a report entitled “journey and take-off of China’s polyether polyol industry”.

Dr. Feng Yanli, senior scientist of Dow chemistry

Dr. Feng Yanli, senior scientist of Dow chemistry, made a keynote report entitled “waterborne polyurethane technology and the application of Syntegra PUD in artificial leather”.

Xue Cong, chemical industry analyst of Guosen Securities

Xue Cong, a chemical industry analyst at Guosen Securities, made a keynote report entitled “the boom around C keeps rising and a hundred schools of thought contend for a variety of processes”.

容威聚氨酯有限公司采购部经理-袁启超.png)

Yuanqichao, purchasing manager of Wanhua chemical (Yantai) Rongwei Polyurethane Co., Ltd

Liu xianbo, R & D Manager of Wanhua Chemical Co., Ltd

Yuan Qichao, manager of procurement department of Wanhua chemical (Yantai) Rongwei Polyurethane Co., Ltd., and Liu xianbo, R & D Manager of Wanhua Chemical Co., Ltd., successively shared the theme of “development prospect of Po and polyether supply and demand”.

Xiao Jie, deputy general manager of Suzhou antway Valve Co., Ltd

Xiao Jie, deputy general manager of Suzhou antway Valve Co., Ltd., made a report entitled “selection and intelligent manufacturing of propylene industrial production units and tank farm emergency shut-off valves”.

On the afternoon of December 17, the meeting was presided over by Li Jian, executive vice president of Shandong Yinuowei new materials Co., Ltd.

Li Jian, executive vice president of Shandong Yinuowei New Material Co., Ltd

Lin min, professor level senior engineer of Sinopec Petrochemical Research Institute

Lin min, professor level senior engineer of Sinopec Petrochemical Research Institute, delivered a keynote report entitled “technical development and industrial application of propylene hydrogen peroxide to propylene oxide”.

Tang Yupeng, marketing manager of Liaoning Glacier Enterprise Group Co., Ltd.

Tang Yupeng, marketing manager of Liaoning Glacier Enterprise Group Co., Ltd., discussed “Glacier coolant” to solve the corrosion problem of coolant in Po production.

Meng Yuezhong, director of the Institute of environmental materials, Sun Yat sen University

Meng Yuezhong, director of the Institute of environmental materials of Sun Yat sen University, made a report entitled “research progress of biodegradable carbon dioxide based semi aromatic copolymers”.

Dr. Shen Chong, liming chemical research and Design Institute Co., Ltd

Dr. Shen Chong of Liming chemical research and Design Institute Co., Ltd. made a keynote report entitled “propylene oxide supporting hydrogen peroxide technology”.

科技有限公司近红外产品北方区经理-蒲乾坤.png)

Pu Qiankun, manager of near infrared products North area of Brooke (Beijing) Technology Co., Ltd

Pu Qiankun, manager of near infrared products of Brooke (Beijing) Technology Co., Ltd., made a report entitled “Application of Brooke online near infrared spectroscopy detection technology in po-ppg-pu industry”.

科技有限公司-尹华-总经理.png)

Yin Hua, general manager of Haitai mingchuang (Beijing) Technology Co., Ltd.

Yin Hua, general manager of Haitai mingchuang (Beijing) Technology Co., Ltd., made a report entitled “csspo cleaner production technology”.

Ning Xiaolong, senior engineer of Shandong Yinuowei New Material Co., Ltd

Ning Xiaolong, senior engineer of Shandong Yinuowei new materials Co., Ltd., made a keynote report entitled “brief analysis of the market status and development trend of polyether polyols”.

On the morning of December 18, we continued our wonderful report under the chairmanship of Ji Xiangyang, general manager of Shanghai Qike fluorosilicone Material Co., Ltd.

Ji Xiangyang, general manager of Shanghai Qike fluorosilicone Material Co., Ltd

Jing Xiaodong, deputy general manager of Zibo Dexin federal Chemical Industry Co., Ltd

Jing Xiaodong, deputy general manager of Zibo Dexin federal Chemical Industry Co., Ltd., made a keynote report entitled “polyether polyol production technology and application of new products”.

Li Chengzhang, chief engineer of Linyi scorui polyurethane material Co., Ltd

Li Chengzhang, chief engineer of Linyi scorui polyurethane materials Co., Ltd., made a keynote report entitled “biomass polyols and their applications”.

Shanghai Qike fluorosilicone Material Co., Ltd. Ji Congqi

Ji Congqi of Shanghai Qike fluorosilicone Material Co., Ltd. made a thematic report entitled “Discussion on the quality improvement scheme of polyether polyols”.

Song Baoning, R & D Manager of Jiahua Chemical Co., Ltd., made a keynote report entitled “development of new polyether for hard foam & Application of new monomer in polyether synthesis”.

Chen Hailiang, senior engineer of Shandong Yinuowei Polyurethane Co., Ltd., made a keynote report entitled “application and development of polyurethane elastomer in medical field”.

Zheng Xingyuan, consulting manager of Tiantian chemical network, made a thematic report entitled “new crown year, PO / PPG supply and demand changes and price trend”.

On the afternoon of December 18, the delegates visited Dongyue economic development zone and Maqiao industrial park by bus.

Relying on the fluorosilicone new material cluster of Zibo Dongyue economic development zone and the new material industry cluster of Maqiao chemical industry park, this event will display the development achievements of the new material industry, promote multi-level information communication among government, enterprises, intelligence and association, and promote industrial technical cooperation by organizing a series of activities such as exhibition and exchange, project promotion, investment attraction and report meeting, press conference and exhibition of the new material industry; Attract a number of leading and base enterprises and strong chain, chain extension and chain supplement projects to further accelerate industrial development, improve quality, and promote the accelerated development and continuous upgrading of Zibo new chemical materials industrial cluster.

Meeting site

During the one-and-a-half day meeting, the experts made wonderful speeches. The delegates listened carefully. The chemical industry park and relevant equipment manufacturers interacted with the guests, seized the opportunity to enhance understanding and strive for cooperation opportunities.

Working principle and effect of evaporative condenser

Evaporative condenser is an efficient heat exchange equipment. It has the advantages of high heat transfer efficiency, energy saving, compact structure and convenient installation. The evaporation absorption capacity (latent heat) of equal quality water at room temperature is 115 times that of heat absorbed by water temperature rising by 5 ℃, which is the fundamental reason for water and power saving of evaporative condenser. It is widely used in large-scale chemical industry, medicine, steel, air conditioning, coal mine, nitrogen fertilizer and so on. It is also practiced in gas cooling, condensation and liquid cooling in ammonia synthesis, methanol synthesis, gas compression, distillation and waste heat recovery.

Working principle of evaporative condenser

The evaporation of some water is mainly used to take away the heat released by the condensation process of the gaseous refrigerant. The high-temperature gaseous refrigerant enters the coil from the refrigerant inlet at the upper part of the coil and exchanges heat with the spray water and air outside the coil. The gaseous refrigerant is gradually condensed into liquid and flows out from the refrigerant outlet at the lower part. The cooling water is sent to the spray system above the condensing coil by the water pump, and evenly sprayed on the outer surface of the condensing coil through the water distributor to form a thin water film. After the spray water and air absorb heat, the temperature rises, part of the water changes from liquid to gaseous, and a large amount of heat is taken away by the latent heat of evaporation. The rest of the water falls back to the lower collecting tank, and then sent to the spray system by the circulating water pump for recycling; The water droplets entrained in the air are blocked by the dehydrator and fall back to the water collection.

Structural characteristics of evaporative condenser

Countercurrent evaporative cooling: it is a kind of evaporative cooling that only uses the latent heat of water for heat exchange. It has large heat exchange area and is not easy to produce ice blockage and dirty blockage. It can operate in various environments, especially in the north. It has good effect and good effect without water in winter. The form of air inlet is countercurrent air inlet at the bottom, which alternates inversely with the spray water at the lower part to form saturated hot and humid air. The heat is discharged from the top fan. The water is recovered by the dehydrator with special structure and recycled in the water collecting tank. There is no heat exchange filler in the internal space, freeing up more space to increase the unit heat dissipation area of the coil. More compact structure and small land occupation. It is especially suitable for the situation that the outlet water temperature is close to the local wet bulb temperature.

Application fields of evaporative condenser

It is widely used in large-scale chemical industry, medicine, steel, air conditioning, coal mine, nitrogen fertilizer, gas cooling, condensation and liquid cooling in ammonia synthesis, methanol synthesis, gas compression, distillation and waste heat recovery.

In terms of structure, evaporative condenser is a combination of ordinary water-cooled condenser, cooling tower, water pump and pipeline connection of water system. It has the advantages of power saving, water saving and convenient installation. It has the characteristics of small floor area and convenient maintenance. However, there are essential differences in the principle of heat exchange. The water-cooled condenser uses the sensible heat of water to absorb the heat of refrigerant to achieve the purpose of refrigeration, while evaporative cooling uses the latent heat of water, that is, the evaporation of water at room temperature to absorb the heat to achieve the purpose of cooling. The heat absorbed by the evaporation of water of the same quality is 116 times that when the water temperature rises by 5 degrees. Therefore, when taking away the same heat, the water consumption of evaporative cooling is much lower than that of water-cooled condenser, which is also the fundamental reason for water and power saving of evaporative cooling.

Here he is! Here he is! CPHI world pharmaceutical raw materials China exhibition is coming to us!!!

Count the days. In two days, CPHI China 2020, the annual grand finale of the pharmaceutical industry, will open, welcoming more than 3000 exhibitors and more than 70000 online and offline visitors at home and abroad.

What is CPHI China?

CPHI China, the full name of the world pharmaceutical raw materials China exhibition, was introduced to China in 2001 and the 20th world pharmaceutical raw materials China exhibition will be held in 2020. It is a world-famous one-stop vertical trade and exchange event in the pharmaceutical industry. It closely follows the industrial policies at home and abroad, grasps the innovation trend in the industry, makes use of rich industrial resources, and provides professionals with services from pharmaceutical raw materials, contract customization, biopharmaceutical, pharmaceutical machinery The integrated solution from packaging materials to laboratory instruments will expand global contacts for domestic pharmaceutical enterprises. This exhibition will have 70000 professional visitors from more than 140 countries and regions at home and abroad.

Is it a little exciting to see here?

Has the scene of stars gathering and heroes gathering been depicted in your head?

Have you been unable to control the pace of departure and want to fly to Shanghai?

Good news for you – we’re here too!

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, the three major problems of traditional coolant “corroding equipment, low efficiency and polluting the environment” are solved, and the service life of refrigeration equipment is prolonged by more than twice.

The R & D center of the company was awarded by the provincial Ministry of science and technology to Liaoning engineering technology center. It has Liaoning liquid heat transfer medium laboratory and glacier heat transfer medium testing center, which can carry out authoritative testing on various physical and chemical indexes of ultra-low temperature heat transfer medium. Since 2000, it has won more than 30 awards, including more than 20 awards at or above the provincial level. It has successively obtained 14 national patents, including 11 invention patents and utility model patents.

If you want to know more about our partners, please remember that our booth number is e6e42. Please refer to the route below to enter area E6. After entering, you can find E42 and see us!

This time, the glacier coolant also prepared a turntable lottery for you. The mysterious prize is waving to you~

It’s time to show your luck!