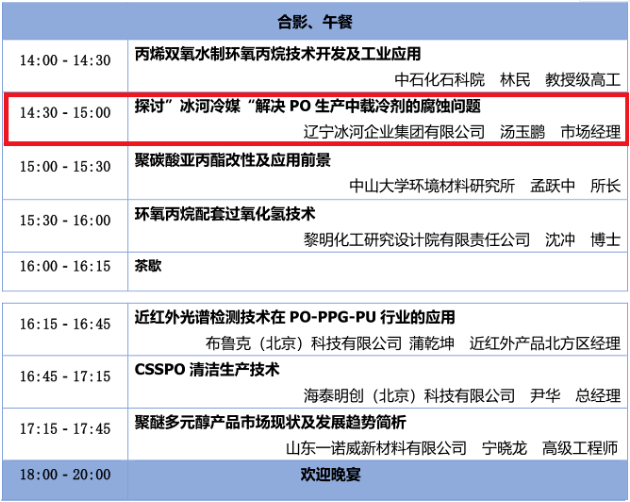

2020 China PO-PPG-PU industrial chain high quality development forum is meeting you in Zibo

With the gradual improvement of refining and chemical integration, propane dehydrogenation and MTO capacity in China, propylene resources are becoming more and more abundant, providing sufficient raw materials for propylene oxide industry. New processes such as HPPO, CHP and POSM are becoming more and more mature, and new projects are increasing; As a large downstream chain of Po industry, PPG-PU industry will face many challenges in the future, such as technology optimization, quality upgrading and market development. The development of PO-PPG-PU industry chain is about to enter a new pattern.

In order to promote the high-quality development of PO-PPG-PU industrial chain and meet market challenges. Glacier refrigerant invites you to participate in the “2020 China PO-PPG-PU industrial chain high quality development forum” held by the polyol Professional Committee of China Polyurethane Industry Association and Beijing United Nations new material technology center in Zibo, Shandong Province from December 16 to 18, 2020.

Industry experts and industry elites gathered together to discuss hot issues in the industrial chain. Glacier coolant will make a technical report on the corrosion of metal equipment by coolant in PO-PPG-PU production process.

At the same time, the “2020 first Zibo Chemical new materials” four new “exhibition was held.

【Glacier Coolant】will be waiting for you at “Zibo Convention and Exhibition Center – booth a11”.

Our booth looks like this. Don’t go wrong!↑

LM series glacier coolant, the leading product of glacier coolant Technology Co., Ltd., is used in refrigeration fields such as pharmacy, chemical industry, refrigeration, HVAC and so on. The products have more than 30 models, and the application range is – 135 ℃ ~ 350 ℃, which can fully meet various needs of secondary refrigeration system.

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, the three major problems of traditional coolant “corroding equipment, low efficiency and polluting the environment” are solved, and the service life of refrigeration equipment is prolonged by more than twice.

Picture (first on the left: Glacier coolant LM-4, second on the left: 25% saline, third on the left: 30% saline)

The company has 2000 + stable customers in the pharmaceutical industry, chemical industry, refrigeration industry, food industry, scientific research institutes and other fields. Professional R & D personnel, excellent sales team and perfect after-sales service, “Glacier coolant” is your high-quality partner!

The third 2020 Symposium on pharmaceutical and chemical process safety and safety production management was successfully held

On November 27, 2020, the third 2020 Symposium on process safety and safety production management of pharmaceutical and chemical industry, sponsored by the state of chemical industry and the pharmaceutical and chemical industry professional committee of China Chemical Enterprise Management Association, was successfully held in Jinan, Shandong Province.

Members of the delegation of our company, Wang Xinmiao from the sales department, Tang Yupeng and Zhang Meng from the marketing department attended the meeting

The background of this meeting is:

Due to the high risk, strict operation requirements and operation level of its production process and production technology, the probability of danger is quite large, which is related to the life safety of its employees and the vital interests of the enterprise. How to ensure safe production, how to control and reduce the risk coefficient, determine the risk degree of reaction process, so as to improve the design of safety facilities, improve risk control measures, improve the production safety of pharmaceutical and chemical enterprises, carry out safe production management, and ensure the development and operation of enterprises.

The seminar was taught by 13 teachers, 8 enterprises placed booths at the meeting site, and nearly 200 people attended the meeting.

On November 27, pan Guojun, general manager of Jinan aikesbote Safety Technology Consulting Co., Ltd., gave a lecture on chemical safety leadership and execution

Chen Wanghua, professor and doctoral supervisor of the Department of safety engineering, School of chemical engineering, Nanjing University of technology, gave a lecture on thermal risk problems in chemical process and their countermeasures

Wang Jianna, deputy general manager of Shandong Runbo Biotechnology Co., Ltd. and director of process safety laboratory, lectured on the early combination of process, engineering, safety and reaction heat research

Wu Zhanjun of Shanghai Yurui Management Consulting Co., Ltd. lectured on Cause Analysis and preventive measures of common electrical accidents

During the tea break, everyone went to each booth for warm exchanges

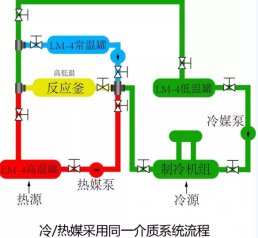

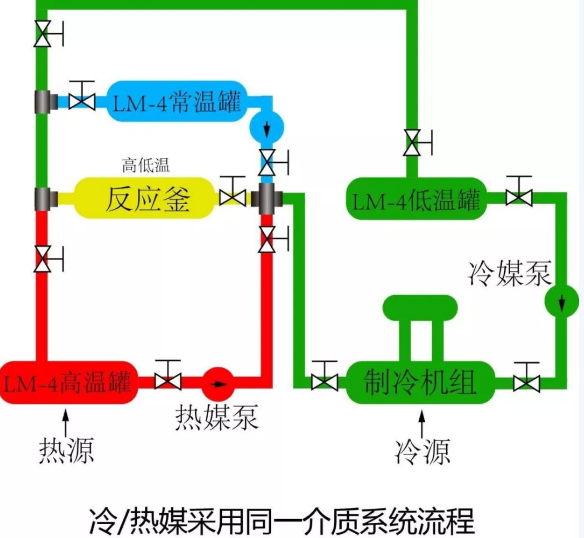

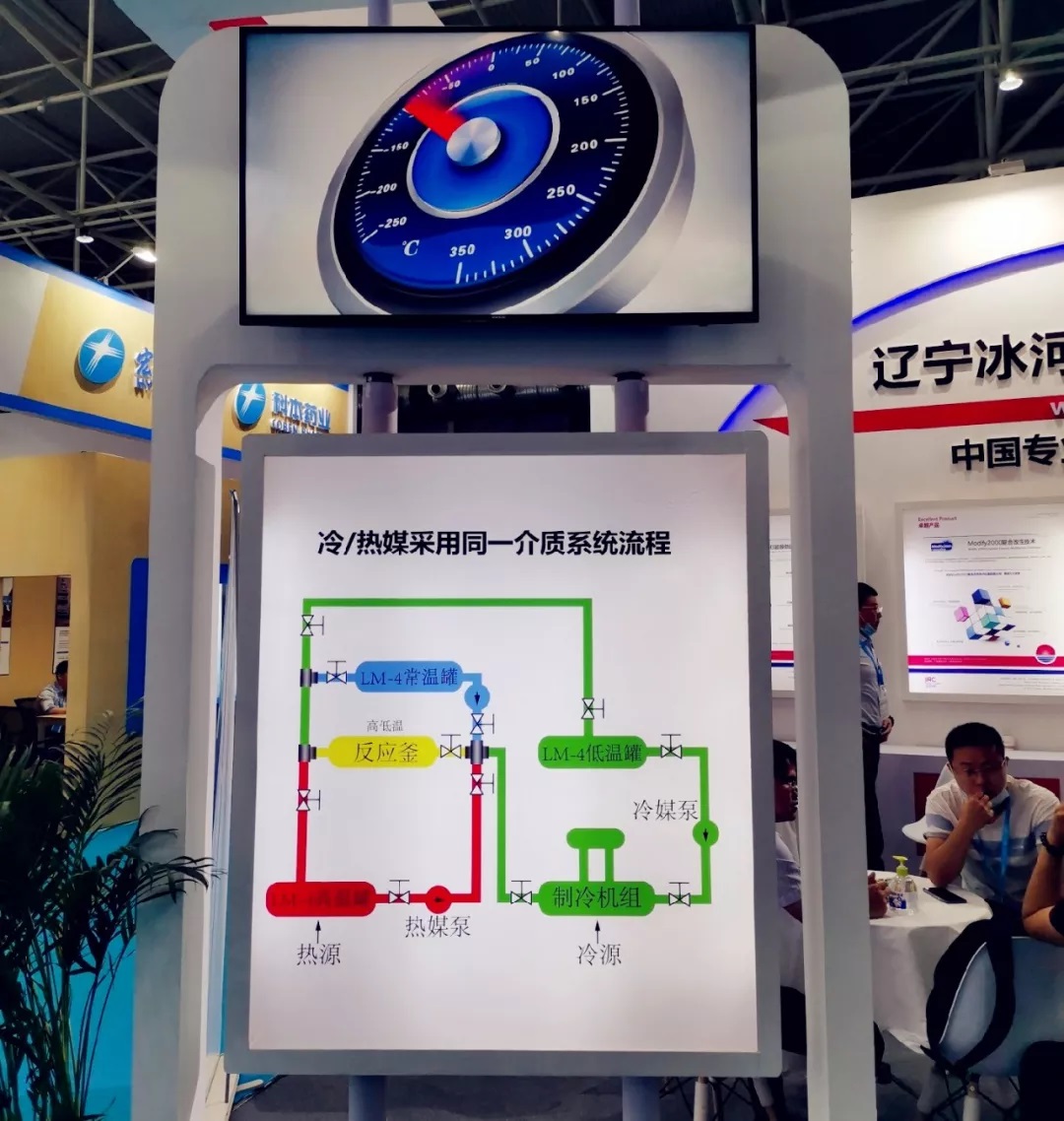

Glacier coolant Technology Co., Ltd. has in-depth cooperation with pharmaceutical, chemical, refrigeration and other industries. In view of the defects of the conventional cold and heat switching process, the process is optimized to LM-4 glacier coolant heat exchange control system as shown in the figure.

Advantages of LM-4 glacier coolant heat exchange control system:

(1)More simplified equipment

If the production process requires high, medium and low working temperatures, the new system only needs to be equipped with one heating device, one closed cooling water tower and one refrigeration unit.

(2)Simplified piping system

Because the systems are closed systems, the design and installation of pipeline system are more simplified. There is no need to install steam traps or compressed air pipes for hot equipment.

(3)Easier operation

In the same equipment, when three different temperature media are switched according to the process requirements, it is only necessary to switch the valve as needed. There is no need to worry about the cross flow of different types of heat exchange media. This is also a problem that the heat exchange system is worried about before optimization.

4)The amount of maintenance is greatly reduced

Because LM-4 glacier coolant has good rust resistance and adopts LM-4 glacier coolant for both cooling and heating media, it can prolong the service life of pipelines and equipment. If you do better in valve selection and installation process, the phenomenon of running, dripping and leakage that has plagued the pharmaceutical and chemical industries will be eliminated, and the on-site management work can also be done better.

(5)Equipment investment and operation cost can be reduced

Since the heat exchange systems with the same medium at three temperatures are closed systems, the water treatment system of steam boiler, circulating water tank in medium temperature system, salt water tank and chemical salt tank can be omitted in the initial construction. At the same time, the daily operation also eliminates the operation and operation costs such as the treatment and renewal of water treatment resin, regular desilting of circulating water tank and salt water replenishment.

After the tea break, Hu Xiaoyong, director of Shanghai Lanbao Environmental Protection Technology Co., Ltd., shared the key points of VOCs governance under the new situation

Tang bin, executive director of Beijing bianda Technology Co., Ltd., gave a lecture on scene based dynamic risk management and control technology of chemical process

Wei Chuan, general manager of production safety software center of Zhejiang zhongkong Technology Co., Ltd., gave a lecture on the overall solution of digital application of production safety

Deng Zhonghao, product director of METTLER TOLEDO RC1, gave a lecture on the application of RC1 in reaction calorimetry and process safety assessment

Ma Junhai, senior engineer and regional business director of Corning Reactor Technology Co., Ltd., gave a lecture on the intrinsic safety solution of micro reaction technology in the application of pharmaceutical and chemical industry

At about 18 PM, the scene of Corning intrinsic safety – dinner exchange was very lively.

Everyone gathered together and enjoyed the live performance brought by the band and local delicacies.

The tense and exciting lucky draw pushed the atmosphere of the dinner to a climax.

Finally, the banquet ended with laughter.

On November 28, you Xizhong, a production safety expert and senior engineer of Jinan Anke Safety Technology Center Co., Ltd. in Shandong Province, gave a lecture on root cause analysis and Countermeasures of accidents in pharmaceutical and chemical industry

Hu Dengping, manager of dekaida consulting Asia Pacific process safety laboratory, lectured on safety design strategy and safety management system of fine chemical enterprises

Su Zhenyu, founder of Shanghai yunenthalpy Technology Co., Ltd., gave a lecture on how to eliminate fire and explosion accidents in fine chemical enterprises

After the conclusion of the meeting, Shandong Runbo Biotechnology Co., Ltd. invited you to visit the process safety laboratory.

At about 15 pm, the meeting came to a successful conclusion.

Glacier coolant appears in "global matchmaking"

On the evening of November 4, 2020, the third China International Import Expo (hereinafter referred to as “China Import Expo”) kicked off in Shanghai.

The president delivered a keynote speech.

It is pointed out that the Expo will turn exhibits into commodities, exhibitors into investors, exchange ideas and ideas, connect China and the world, become four platforms for international procurement, investment promotion, people to people and cultural exchanges and open cooperation, and become an international public product shared all over the world.

On November 6, the trade fair along the the Belt and Road, a supporting event of the China International Trade Promotion Commission and industrial and Commercial Bank of China, was held in Shanghai National Convention and Exhibition Center. Nearly 400 Chinese and foreign enterprises have conducted one-on-one and face-to-face on-site negotiations. The “global matchmaking” cross-border matchmaking platform independently developed by ICBC provides strong financial support for domestic and foreign enterprises to integrate into the global industrial chain, supply chain and value chain.

With the three financial concepts of “business, intelligence and financing” as the core, global matchmaking will build an intelligent and digital global enterprise community, provide intelligent whole process services, build a global “circle of friends” with information sharing and mutual benefit, and build a long-term and stable new ecosystem of bank government and bank enterprise interaction.

The cross-border matchmaking platform of “global matchmaking” is open to the world free of charge, including three core functions of “global business opportunities”, “matchmaking activities” and “financial services”. The “matchmaking activities” section supports intelligent online and offline cross-border matchmaking activities, covering all links such as global launch, enterprise recruitment, supply and demand matching, business negotiation, tracking and evaluation. Only more than two months after the platform was released, ICBC has organized and carried out many high-quality online cross-border matchmaking activities in China, Malaysia, China and Rwanda, China Africa, China and Myanmar, relying on the “global matchmaking” platform, and more than 75% of enterprises have reached cross-border cooperation intentions.

At the same time, relying on the advantages of financial technology, ICBC continues to innovate financial services. For example, in cooperation with the General Administration of customs, it launched the “cross-border loan” for foreign trade enterprises, which is the first online financing product in the industry that actively provides batch credit and online processing for import and export enterprises based on big data technology and “single window” data information. Taking the initiative to combine the characteristics and advantages of local commerce and trade, design and promote localized products, and successively launch the “foreign trade loan” in Inner Mongolia, the “Qingtian technology loan” in Jiangsu and the “foreign exchange settlement loan” in Suzhou Industrial Park, so as to provide a strong driving force for Regional Opening-up.

Bai Xinmeng, general manager of Glacier coolant Technology (Beijing) Co., Ltd., attended the event.

有限公司总经理白欣萌参加此次活动1.png)

In this event, after several rounds of negotiation, our company had in-depth and friendly exchanges with many enterprises such as lihuayi Group Co., Ltd.

Glacier coolant Technology Co., Ltd. has been deeply engaged in the refrigeration industry for 26 years, committed to anti-corrosion and anti rust solutions, and always takes “leading technology and customer first” as the business philosophy. Taking advantage of the “the Belt and Road, common development” initiative, we will share resources and complement our strengths with enterprises in countries along the belt and road, and join hands to contribute to human civilization!

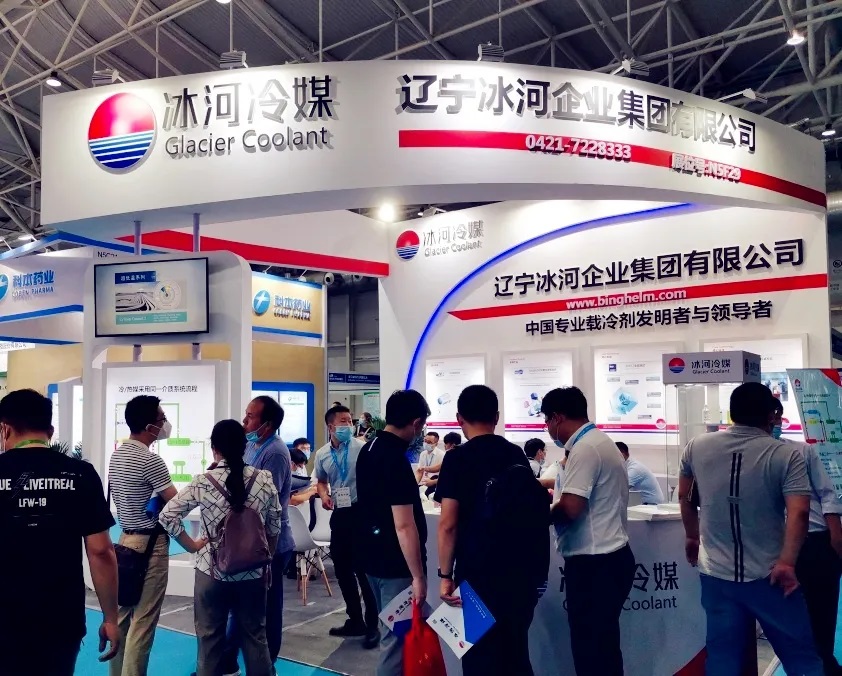

Glacial coolant popular API China API Exhibition

The 84th China international pharmaceutical raw materials / intermediates / packaging / Equipment Fair (APIChina) opened grandly at the International Exhibition Center of Qingdao World Expo City today.

In this exhibition, the glacier coolant proposed optimized solutions for the high and low temperature cold and heat switching system in pharmaceutical and chemical industry, and the on-site consultation broke out.

A professional coolant with both high and low temperature performance. Glacier coolant replaces traditional brine and steam. This system has the following advantages:

- 1、Solve the problem of continuous dilution of brine concentration during hot and cold switching;

- 2、Gas purging is not required for cold and heat exchange;

- 3、The process is simplified, and the hot and cold switching three-way control valve can be realized;

- 4、It does not corrode the equipment and can realize high automation at the same time;

- 5、For the process units with large temperature difference between cooling and heating medium and frequent cold and heat switching, the energy-saving effect is remarkable。

Welcome industry experts to the booth for detailed exchange of our booth number:N5F29!

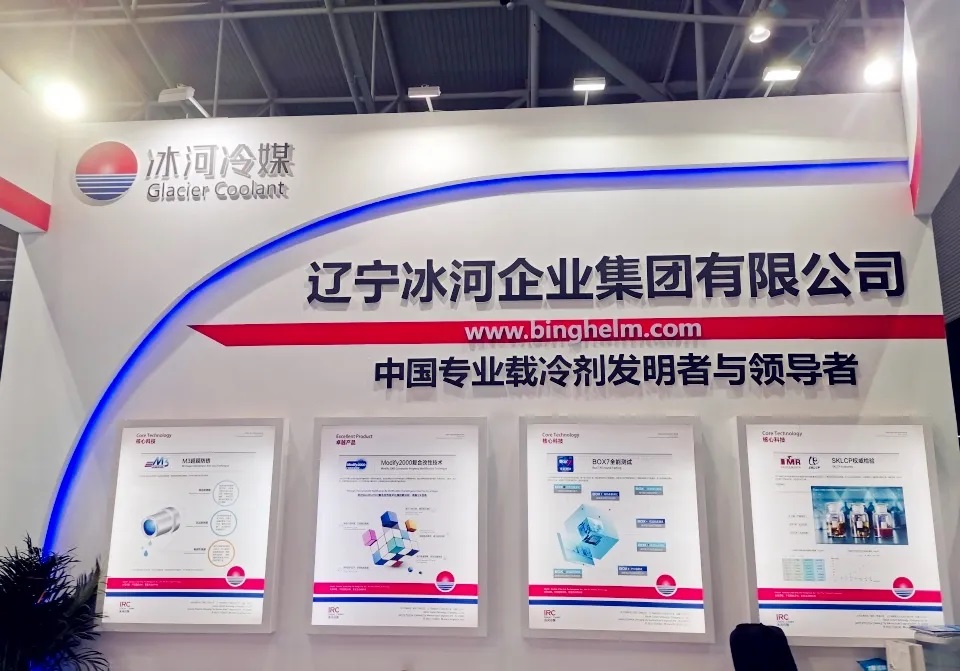

LM series glacier coolant, a new type of coolant with high efficiency, environmental protection, anti-corrosion and low consumption, is a national key new product with its own intellectual property rights and proprietary technology。

“M3 supermodel antirust” technology, “modify2000 composite modification” technology, “box7 all-round test”, and passed the authoritative test of sklcp of Institute of metals, Chinese Academy of Sciences. As a result, the production technology and process level occupy the commanding height in the field of domestic coolant R & D and production, and are moving towards a higher goal.

As of 2018, glacier coolant has more than 2000 customers in various industries in China, covering medicine, chemical industry, refrigeration, food, central air conditioning, etc.

"Fresh blood" of glacier coolant is exported to Southeast Asia, America and other places

China US trade negotiations have experienced many twists and turns, and the world’s major economies are still shrouded in trade protectionism. Superimposing the adverse effects of the current epidemic, it is very difficult for Chinese enterprises to face the overseas market in the era of anti globalization. Recently, as a professional refrigerant for high and low temperature synthesis reaction, glacier coolant has been exported to America and other countries according to the needs of foreign users. At present, despite the difficulties such as the epidemic situation. But glacier coolant has the confidence and courage to overcome everything and serve global users well.

Under the epidemic situation, strict measures have been taken for glacier refrigerant, including twice daily temperature detection, disinfection management several times a day, and vacation measures for some employees, so as to reduce the risk of infection as much as possible. For external personnel, closely detect, disinfect and measure the body temperature to minimize the communication of external personnel. Years ago, I spent these days in tension and busyness. When it came to returning to work after, only a small number of people were selected to work. Under the conditions of strict disinfection, temperature measurement, access control and isolated dining, the ice refrigerant successfully spent this tense epidemic time. Moreover, during the epidemic period, we also successfully delivered batches of ice refrigerant to solve the urgent needs of enterprises in need.

Under the epidemic situation, strict measures have been taken for glacier refrigerant, including twice daily temperature detection, disinfection management several times a day, and vacation measures for some employees, so as to reduce the risk of infection as much as possible. For external personnel, closely detect, disinfect and measure the body temperature to minimize the communication of external personnel. Years ago, I spent these days in tension and busyness. When it came to returning to work after, only a small number of people were selected to work. Under the conditions of strict disinfection, temperature measurement, access control and isolated dining, the ice refrigerant successfully spent this tense epidemic time. Moreover, during the epidemic period, we also successfully delivered batches of ice refrigerant to solve the urgent needs of enterprises in need.

Under the epidemic situation, strict measures have been taken for glacier refrigerant, including twice daily temperature detection, disinfection management several times a day, and vacation measures for some employees, so as to reduce the risk of infection as much as possible. For external personnel, closely detect, disinfect and measure the body temperature to minimize the communication of external personnel. Years ago, I spent these days in tension and busyness. When it came to returning to work after, only a small number of people were selected to work. Under the conditions of strict disinfection, temperature measurement, access control and isolated dining, the ice refrigerant successfully spent this tense epidemic time. Moreover, during the epidemic period, we also successfully delivered batches of ice refrigerant to solve the urgent needs of enterprises in need.

Glacier coolant Technology (Beijing) Co., Ltd., the leading product of glacier coolant Technology (Beijing) Co., Ltd., is applied to the refrigeration industry, which solves the three major problems of traditional refrigerant corrosion equipment, low efficiency and environmental pollution.

Invitation letter | API China, Glacier coolant is with you!

Glacier coolant will participate in the 83rd China International Pharmaceutical API / intermediate / packaging / Equipment Fair (API China) held at Nanchang Greenland International Expo Center from October 10 to 12, 2019. We will welcome you to booth a2a33 with high-quality products and warm service!

Booth number:A2A33

The main products of glacier coolant company are new-type coolant (LM series glacier coolant) with high efficiency, environmental protection, anti-corrosion and low consumption, which has its own intellectual property rights and proprietary technology. It has successively invented the “m3 super model rust prevention” technology, “modify2000 composite modification” technology, “box7 all-round test”, and passed the sklcp authoritative test of the Institute of metals, Chinese Academy of Sciences. As a result, the production technology and process level occupy the commanding height in the field of domestic refrigerant R & D and production, and is moving towards a higher goal.

Glacier coolant this exhibition will propose optimized solutions for the high and low temperature cold and heat switching system in pharmaceutical and chemical industry. A coolant with both high and low temperature will replace the traditional low-temperature brine and high-temperature steam. This system has the following advantages:

- Solve the problem of continuous dilution of brine concentration during hot and cold switching;

- No gas purging is required for cold and heat exchange;

- The process is simplified, and the hot and cold switching three-way control valve can be realized;

- It does not corrode the equipment and can realize high automation at the same time;

- For the process units with large temperature difference between cooling and heating medium and frequent cold and heat switching, the energy-saving effect is remarkable.

Industry experts are welcome to the booth for detailed exchange

As of 2018, glacier coolant has more than 2000 customers in various industries in China, covering medicine, chemical industry, refrigeration, food, central air conditioning, etc. In 2016, in order to meet the market demand, the company invested in the expansion of the new plant and received strong support from the local government, making due contributions to the revitalization of the economy of the old northeast.