On November 27, 2020, the third 2020 Symposium on process safety and safety production management of pharmaceutical and chemical industry, sponsored by the state of chemical industry and the pharmaceutical and chemical industry professional committee of China Chemical Enterprise Management Association, was successfully held in Jinan, Shandong Province.

Members of the delegation of our company, Wang Xinmiao from the sales department, Tang Yupeng and Zhang Meng from the marketing department attended the meeting

The background of this meeting is:

Due to the high risk, strict operation requirements and operation level of its production process and production technology, the probability of danger is quite large, which is related to the life safety of its employees and the vital interests of the enterprise. How to ensure safe production, how to control and reduce the risk coefficient, determine the risk degree of reaction process, so as to improve the design of safety facilities, improve risk control measures, improve the production safety of pharmaceutical and chemical enterprises, carry out safe production management, and ensure the development and operation of enterprises.

The seminar was taught by 13 teachers, 8 enterprises placed booths at the meeting site, and nearly 200 people attended the meeting.

On November 27, pan Guojun, general manager of Jinan aikesbote Safety Technology Consulting Co., Ltd., gave a lecture on chemical safety leadership and execution

Chen Wanghua, professor and doctoral supervisor of the Department of safety engineering, School of chemical engineering, Nanjing University of technology, gave a lecture on thermal risk problems in chemical process and their countermeasures

Wang Jianna, deputy general manager of Shandong Runbo Biotechnology Co., Ltd. and director of process safety laboratory, lectured on the early combination of process, engineering, safety and reaction heat research

Wu Zhanjun of Shanghai Yurui Management Consulting Co., Ltd. lectured on Cause Analysis and preventive measures of common electrical accidents

During the tea break, everyone went to each booth for warm exchanges

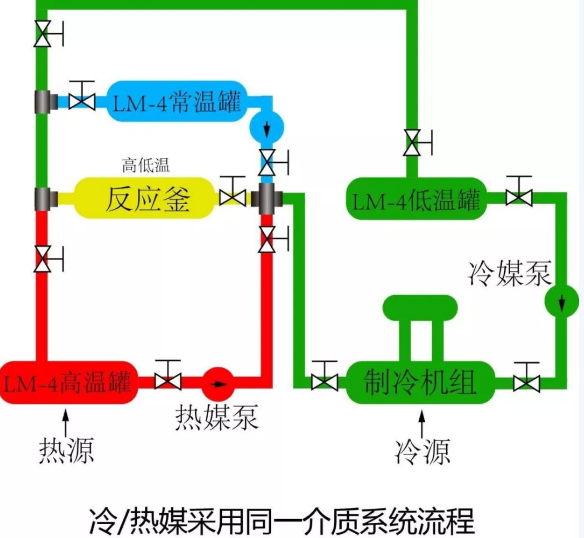

Glacier coolant Technology Co., Ltd. has in-depth cooperation with pharmaceutical, chemical, refrigeration and other industries. In view of the defects of the conventional cold and heat switching process, the process is optimized to LM-4 glacier coolant heat exchange control system as shown in the figure.

Advantages of LM-4 glacier coolant heat exchange control system:

(1)More simplified equipment

If the production process requires high, medium and low working temperatures, the new system only needs to be equipped with one heating device, one closed cooling water tower and one refrigeration unit.

(2)Simplified piping system

Because the systems are closed systems, the design and installation of pipeline system are more simplified. There is no need to install steam traps or compressed air pipes for hot equipment.

(3)Easier operation

In the same equipment, when three different temperature media are switched according to the process requirements, it is only necessary to switch the valve as needed. There is no need to worry about the cross flow of different types of heat exchange media. This is also a problem that the heat exchange system is worried about before optimization.

4)The amount of maintenance is greatly reduced

Because LM-4 glacier coolant has good rust resistance and adopts LM-4 glacier coolant for both cooling and heating media, it can prolong the service life of pipelines and equipment. If you do better in valve selection and installation process, the phenomenon of running, dripping and leakage that has plagued the pharmaceutical and chemical industries will be eliminated, and the on-site management work can also be done better.

(5)Equipment investment and operation cost can be reduced

Since the heat exchange systems with the same medium at three temperatures are closed systems, the water treatment system of steam boiler, circulating water tank in medium temperature system, salt water tank and chemical salt tank can be omitted in the initial construction. At the same time, the daily operation also eliminates the operation and operation costs such as the treatment and renewal of water treatment resin, regular desilting of circulating water tank and salt water replenishment.

After the tea break, Hu Xiaoyong, director of Shanghai Lanbao Environmental Protection Technology Co., Ltd., shared the key points of VOCs governance under the new situation

Tang bin, executive director of Beijing bianda Technology Co., Ltd., gave a lecture on scene based dynamic risk management and control technology of chemical process

Wei Chuan, general manager of production safety software center of Zhejiang zhongkong Technology Co., Ltd., gave a lecture on the overall solution of digital application of production safety

Deng Zhonghao, product director of METTLER TOLEDO RC1, gave a lecture on the application of RC1 in reaction calorimetry and process safety assessment

Ma Junhai, senior engineer and regional business director of Corning Reactor Technology Co., Ltd., gave a lecture on the intrinsic safety solution of micro reaction technology in the application of pharmaceutical and chemical industry

At about 18 PM, the scene of Corning intrinsic safety – dinner exchange was very lively.

Everyone gathered together and enjoyed the live performance brought by the band and local delicacies.

The tense and exciting lucky draw pushed the atmosphere of the dinner to a climax.

Finally, the banquet ended with laughter.

On November 28, you Xizhong, a production safety expert and senior engineer of Jinan Anke Safety Technology Center Co., Ltd. in Shandong Province, gave a lecture on root cause analysis and Countermeasures of accidents in pharmaceutical and chemical industry

Hu Dengping, manager of dekaida consulting Asia Pacific process safety laboratory, lectured on safety design strategy and safety management system of fine chemical enterprises

Su Zhenyu, founder of Shanghai yunenthalpy Technology Co., Ltd., gave a lecture on how to eliminate fire and explosion accidents in fine chemical enterprises

After the conclusion of the meeting, Shandong Runbo Biotechnology Co., Ltd. invited you to visit the process safety laboratory.

At about 15 pm, the meeting came to a successful conclusion.