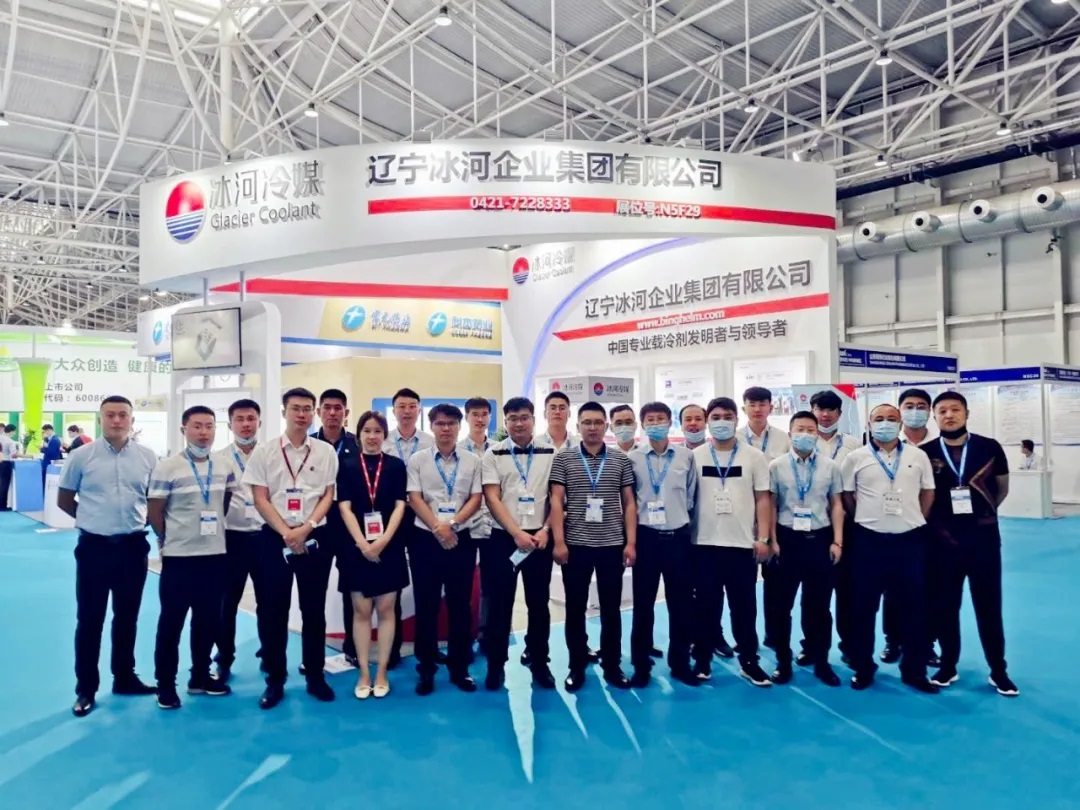

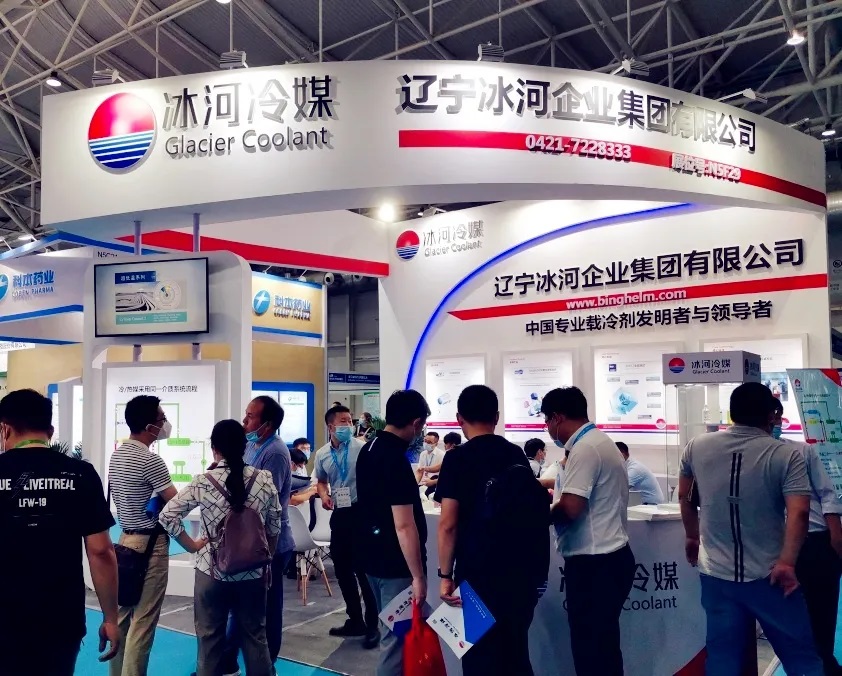

The 84th China international pharmaceutical raw materials / intermediates / packaging / Equipment Fair (APIChina) opened grandly at the International Exhibition Center of Qingdao World Expo City today.

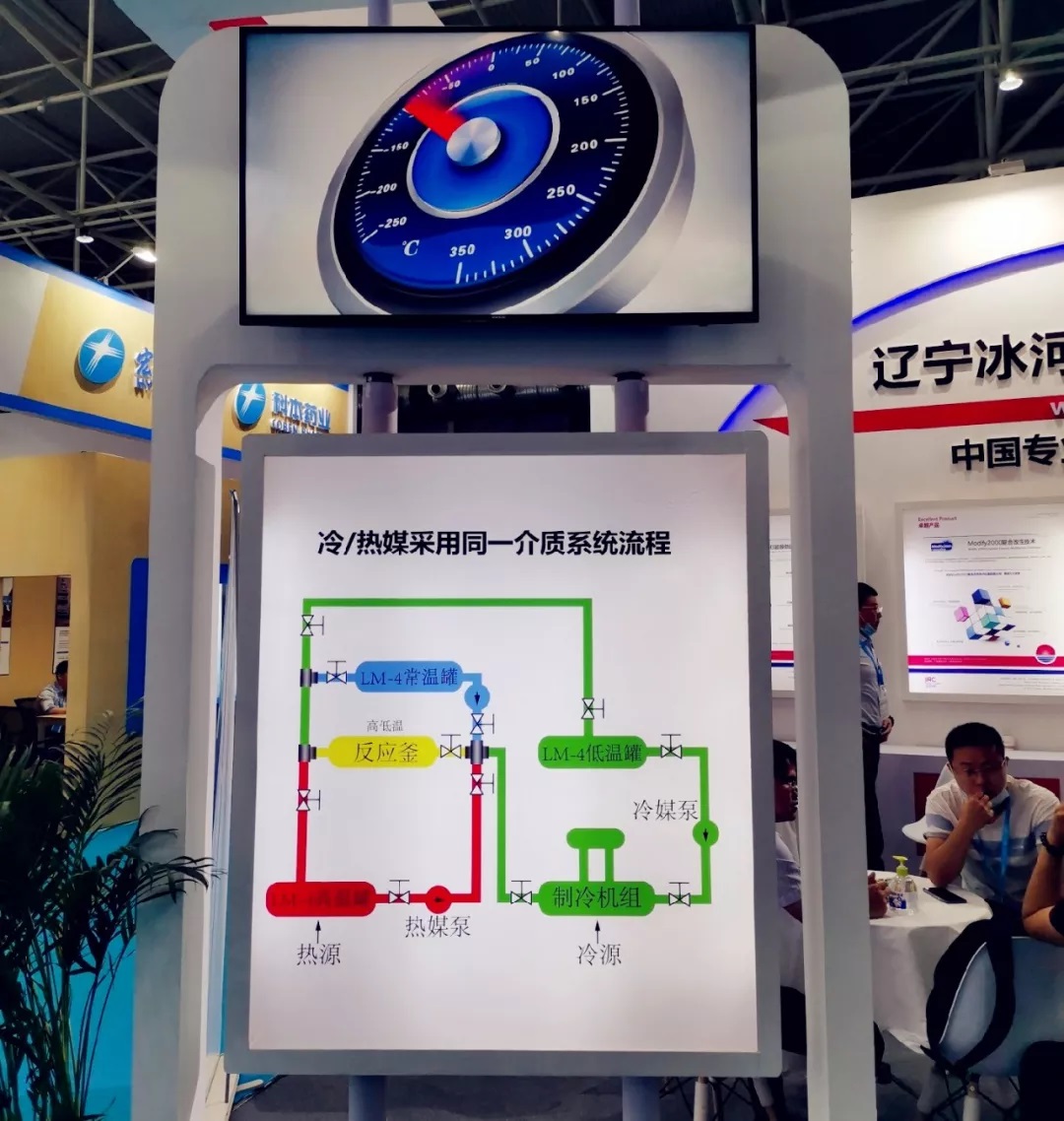

In this exhibition, the glacier coolant proposed optimized solutions for the high and low temperature cold and heat switching system in pharmaceutical and chemical industry, and the on-site consultation broke out.

A professional coolant with both high and low temperature performance. Glacier coolant replaces traditional brine and steam. This system has the following advantages:

- 1、Solve the problem of continuous dilution of brine concentration during hot and cold switching;

- 2、Gas purging is not required for cold and heat exchange;

- 3、The process is simplified, and the hot and cold switching three-way control valve can be realized;

- 4、It does not corrode the equipment and can realize high automation at the same time;

- 5、For the process units with large temperature difference between cooling and heating medium and frequent cold and heat switching, the energy-saving effect is remarkable。

Welcome industry experts to the booth for detailed exchange of our booth number:N5F29!

LM series glacier coolant, a new type of coolant with high efficiency, environmental protection, anti-corrosion and low consumption, is a national key new product with its own intellectual property rights and proprietary technology。

“M3 supermodel antirust” technology, “modify2000 composite modification” technology, “box7 all-round test”, and passed the authoritative test of sklcp of Institute of metals, Chinese Academy of Sciences. As a result, the production technology and process level occupy the commanding height in the field of domestic coolant R & D and production, and are moving towards a higher goal.

As of 2018, glacier coolant has more than 2000 customers in various industries in China, covering medicine, chemical industry, refrigeration, food, central air conditioning, etc.