Heat transfer fluid selection can involve complicated, multi-dimensional decisions where factors such as thermal stability,pumpability, pressure requirements, and more must be weighed in an effort to achieve the optimum balance of performance and economy in your particular system. However, you may be able to narrow your range of options with a few basic decisions.

First, choose a synthetic organic fluid, a silicone fluid or an inhibited glycol-based fluid based on your temperature requirements. If your heat transfer application has a maximum-use temperature requirement above 175˚C (350˚F), consider a synthetic organic or silicone fluid. For temperatures lower than 175˚C (350˚F), or if you need freeze protection for a water based system, consider an inhibited glycol-based fluid.

Synthetic organic and silicone fluids are thermally stable at temperatures up to 400˚C (750˚F). While operating at these elevated temperatures, they exhibit vapor pressures much lower than steam, making them more practical and less expensive to use. Fluids with broad operating temperature ranges offer high temperature stability and low temperature pumpability.

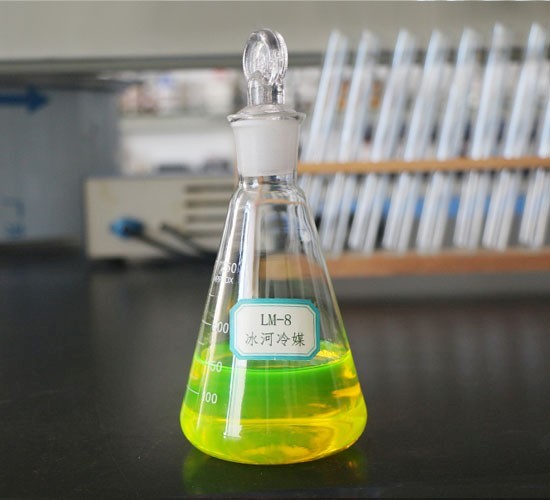

Inhibited glycol-based fluids are solutions of water and inhibited glycols operating below 175˚C (350˚F). The concentration of glycol in the fluid directly affects its performance properties.

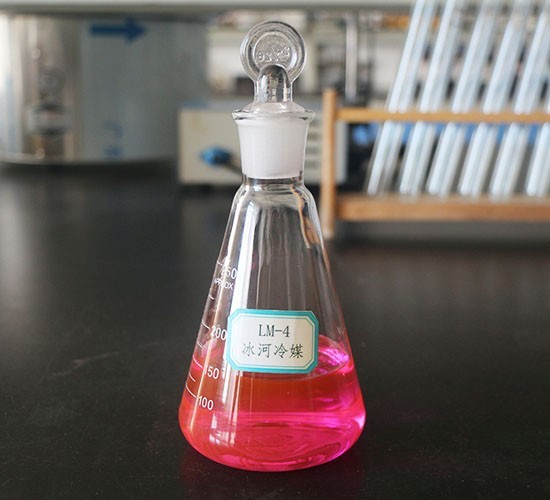

If an inhibited glycol-based fluid will meet your system’s thermal requirements, you can choose between ethylene glycol- and propylene glycol-based fluids. In most applications ethylene glycol-based fluids are preferred because of their lower viscosity and resulting superior heat transfer efficiency.

However, local regulations or a specific application may require the use of a propylene glycol-based fluid. Propylene glycols are commonly used in applications in which a fluid low in acute oral toxicity is required, for example, where incidental contact with drinking water is possible and in food processing applications.