Discussion on construction technology of hydrogen refueling station

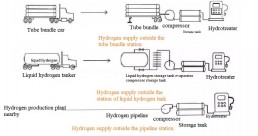

There is no hydrogen production unit in the external hydrogen supply hydrogen refueling station. Hydrogen is transported from the hydrogen plant to the hydrogen refueling station through long tube trailers, liquid hydrogen tankers or hydrogen pipelines, compressed by the compressor and transported to the high-pressure hydrogen storage bottle for storage, and finally filled into fuel cell vehicles through the hydrogen dispenser.

According to different hydrogen storage modes, it can be further divided into high-pressure gas hydrogen station and liquid hydrogen station,About 30% of the world’s liquid hydrogen storage and transportation stations are hydrogen refueling stations, which are mainly distributed in the United States and Japan. At present, China is all high pressure gas hydrogen stations.Compared with the gas hydrogen storage and transportation, the liquid hydrogen storage and transportation hydrogenation station occupies a smaller area and has a larger storage capacity, but it is also more difficult to construct, which is suitable for large-scale hydrogenation.

Fig. 1 Technical Route of External Hydrogen Supply and Hydrogenation Station

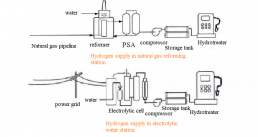

The internal hydrogen production and hydrogenation station is equipped with a hydrogen production system. The hydrogen production technologies include hydrogen production by electrolysis of water, hydrogen production by natural gas reforming, and hydrogen production by renewable energy. The hydrogen produced in the station generally needs to be purified, dried, and then compressed, stored, and injected.Among them, electrolytic water hydrogen production and natural gas reforming hydrogen production technologies are most widely used in the station hydrogen production and hydrogenation stations because of the ease of equipment installation and high degree of automation, and the natural gas reforming technology can be developed based on the construction of natural gas infrastructure. The European hydrogen production and hydrogenation stations mainly use these two hydrogen production methods.

Fig. 2 Technical route of internal hydrogen production and hydrogenation station

According to different hydrogen supply pressure levels, the hydrogen refueling station is divided into two types of hydrogen supply pressure: 35MPa and 70MPa.

Most foreign markets use 70 MPa,Restricted by the development of existing compressor and hydrogen storage bottle technologies, most domestic hydrogen refueling stations use 35 MPa.When 35 MPa pressure is used for hydrogen supply, the working pressure of the hydrogen compressor is 45 MPa, and the working pressure of the high-pressure hydrogen storage cylinder is 45 MPa;When 70 MPa pressure is used for hydrogen supply, the working pressure of the hydrogen compressor is 98 MPa, and the working pressure of the high-pressure hydrogen storage cylinder is 87.5 MPa.

On the basis of the original or new gas station and gas station, add hydrogenation functional facilities to make the station have multiple functions such as refueling, gas refueling, hydrogenation, etc.According to the Technical Code for Hydrogenation Station (GB 50516-2010), the hydrogen refueling station can be built in a single station, requiring relocation and high input cost;The oil hydrogen hybrid station is the development direction of the future hydrogen refueling station, which can also avoid the need for more space and time for electric vehicle charging.

Glacier coolant provides customers with coolant to ensure that the temperature is kept at – 40 ° C when hydrogen is injected, alleviate the temperature rise of pressure drop, and is widely used in hydrogen refueling stations.Through long-term research, our company has invented glacier coolant products and applied for national patents.He has successively invented “M3 super film rust prevention” technology, “Modify2000 composite modification” technology and “Box7 all-around test”.The problems such as corrosion of equipment, narrow temperature range and potential safety hazards caused by salt water, ethylene glycol and dichloromethane, which are substitutes of traditional coolant, have been solved.In addition to hydrogen refueling stations, they are also widely used as industrial low temperature load coolant, pharmaceutical high and low temperature load coolant, industrial antifreeze, central air-conditioning antifreeze, solar antifreeze, automobile antifreeze, laser antifreeze, etc.

Application of Glacier coolant Modified Polyfluorochemicals in the Industry

Immersion cooling of power devices

From high-speed electric trains to wind turbines, to electric motors in heavy bulldozers and personal electric vehicles (EVs),The ability to control voltage accurately on a large scale makes many efficient and powerful innovative ideas possible.However, the devices that manage this process, such as power inverters, thyristors, variable speed drives and other power devices, need to be efficiently cooled.

Glacier coolant modified polyfluorochemicals can be used as an ideal immersion cooling working fluid for variable voltage power devices.These insulating liquids can safely contact electronic equipment, and can achieve efficient and uniform cooling of power devices by using single-phase or two-phase immersion cooling.These liquids have a wide operating temperature range, excellent material compatibility and easy maintenance, making the immersion cooling method based on the Glacier coolant modified polyfluorochemicals an excellent alternative to the air, water or oil cooling method. The product achieves all of these properties without compromising on worker safety or environmental sustainability.

The progress of power devices has pushed the whole world forward.Our modified fluoride solution can keep these equipment cool by simple, efficient and high-performance immersion cooling.Compared with the existing cooling methods, the immersion cooling of glacier coolant modified fluoride solution has obvious advantages. It can be considered for future power device applications, such as high-speed railways, heavy machinery, wind turbines, high-speed elevators, and automobiles.

Data center cooling

The rise of data economy has fundamentally changed people’s lifestyle;Moreover, the current world is always online and highly integrated, which is driving enterprises to operate at a faster and faster speed.Almost all aspects of people’s daily life depend on the tasks running inside the data center.However, the operation of these data centers requires high costs in terms of energy consumption, water use, floor space, etc.Obviously, what we need is a faster, smarter and more sustainable data center. By transferring the data center from traditional cooling mode to submerged liquid cooling using glacier modified polyfluorochemicals, enterprises can manage the impact on costs and natural resources.

Glacier coolant modified polyfluorochemicals can be used in the following systems:

Large scale data center

No matter where you decide to locate, you can deploy a data center with a more consistent cooling infrastructure worldwide.Reducing or eliminating air cooling infrastructure (such as chillers, telecommunications/network equipment, facility floor space, etc.) to a greater extent can meet new workload demands while reducing capital expenditure.With the improvement of cooling efficiency, the cost of special power required for auxiliary cooling will be reduced.Reduce the power efficiency index (PUE) and the use of water resources. When the power efficiency index is as low as 1.03, a more energy efficient and sustainable data center can be built.

Supercomputing Center

By increasing power efficiency, immersion cooling can now support new or more compute intensive workloads that are difficult to cool in an efficient and cost-effective manner with traditional cooling solutions. Reduce operating expenses. With the improvement of cooling efficiency, the cost of special power required for auxiliary cooling will be reduced.

Enterprise High Performance Computing

Support new or more compute intensive workloads that are difficult to cool in an efficient and cost-effective manner with traditional cooling solutions. Lower latency. Delay sensitive workloads can be run in more intensive, space optimized data centers, or closer to users’ server cabinets to help reduce latency. Improve hardware reliability. The lower chip junction temperature, the reduction of temperature fluctuations and hot spots improve the operation reliability; At the same time, the necessary moving parts in traditional cooling methods are reduced to a large extent, thereby reducing common hardware failures.