CPhI & P-MEC China 2020has come to a successful conclusion!

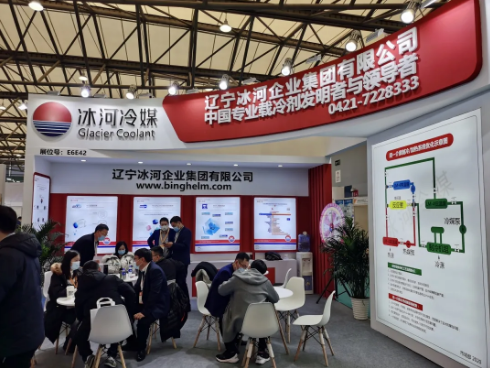

Glacier exhibition site

(Exhibitor glacier coolant)

Glacier coolant and colleagues from all walks of life have worked together to overcome difficulties and forge ahead in this unusual year. Let’s review the unique style of glacier coolant in this CPHI.

Glacier exhibition review

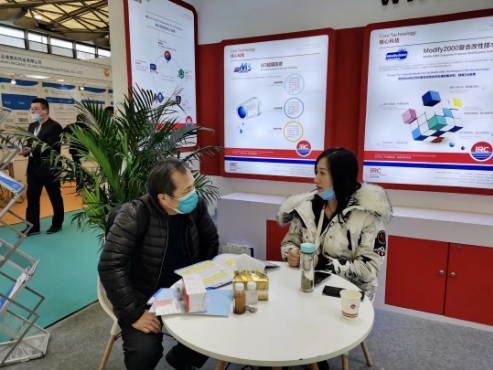

(Fan Dongmei, executive vice president of glacier coolant, introduced the company’s products to visitors)

(There was an endless stream of visitors in front of the glacier coolant booth)

(Visitors come to learn about glacier coolant)

(Leave contact information for each other for in-depth understanding after the meeting)

In this exhibition, glacier coolant not only provides one-to-one answer service, but also allows visitors to deeply understand and trust glacier coolant.

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, it solves the three major problems of traditional refrigerant “corroding equipment, low efficiency and polluting the environment”, and prolongs the service life of refrigeration equipment by more than twice.

The company has more than 2000 stable customers in the pharmaceutical industry, chemical industry, refrigeration industry, food industry and scientific research institutes.

2020 is coming to an end. Thank you for your support and love to binghe. We will continue to uphold the belief of “taking customers as our home, enterprises as our home and binghe as our pride” and continue to provide customers with professional and high-quality products. Remember the original heart, move forward firmly, and look forward to your next encounter!

Congratulate! 2020 China po-ppg-pu industrial chain high quality development forum was successfully held in Zibo!

In recent years, Zibo has vigorously implemented the “top four” industrial climbing plan of new materials, intelligent equipment, new medicine and electronic information, and initially formed four advantageous industrial clusters of fluorosilicone materials, polyurethane, polyolefin and engineering plastics. New chemical materials have developed into one of the core competitive industries in Zibo.

On December 16, the third China Zibo International Conference on new chemical materials industry was grandly opened in Zibo Convention and Exhibition Center. The industrial conference was hosted by China fluorosilicone organic materials industry association, Huantai County People’s government and China Epoxy Resin Industry Association (Preparatory), organized by Beijing fluorosilicone Technology Development Co., Ltd., Beijing Sinochem new materials technology center, Dongyue fluorosilicone Technology Group Co., Ltd. and Zhejiang Lingzhi new materials Co., Ltd., and organized by China Petroleum and Chemical Industry Federation, Zibo Municipal People’s government, China Polyurethane Industry Association Supported by China Membrane Industry Association, the event will take place from December 16 to 18.

Song Xianzhu, Secretary of the Party committee and vice president of China Electronic Information Industry Development Research Institute, Cao Xianjun, vice chairman and Secretary General of China fluorosilicone organic materials industry association, Xu Dingming, counsellor of the State Council and former director of the Energy Bureau of the national development and Reform Commission, Liu Weiping, deputy chief Engineer of Shanghai Aircraft Manufacturing Co., Ltd. of China Commercial Aircraft Corporation, and LV Guoguo, Secretary General of China Polyurethane Industry Association, Xie Hongliang, Deputy Secretary General of China epoxy resin Association, attended the opening ceremony; Ma Xiaolei, deputy secretary of Zibo Municipal Party committee and acting mayor, attended the opening ceremony and delivered a speech; The ceremony was presided over by song Zhenbo, member of the Standing Committee of the municipal Party committee and vice mayor, and attended by Zong Zhijian, Secretary General of the municipal government.

Ma Xiaolei, deputy secretary of Zibo Municipal Party committee and acting mayor, delivered a speech

Song Zhenbo, member of the Standing Committee of Zibo Municipal Party committee and vice mayor, presided over the meeting

Speech by Cao Xianjun, vice president and Secretary General of China fluorosilicone Organic Materials Industry Association

Speech by Xie Hongliang, Deputy Secretary General of China Epoxy Resin Industry Association

Jia Gang, Secretary of Huantai County Party committee, attended the opening ceremony

Bian Jiangfeng, deputy secretary of Huantai County Party committee and head of Huantai County, attended the opening ceremony

From December 17 to 18, the “2020 China po-ppg-pu industrial chain high quality development forum” was successfully held in Zibo, Shandong Province, supported by Zibo Municipal People’s government, hosted by China Polyurethane Industry Association and Huantai County People’s government, jointly organized by polyol Professional Committee of China Polyurethane Industry Association and Beijing Sinochem new material technology center, and co organized by Suzhou antway Valve Co., Ltd!

Experts and representatives from nearly 100 units in the upstream and downstream production enterprises, technical research units, new product development institutions, supporting equipment enterprises and financial investment institutions of propylene oxide (PO) – polyether polyol (PPG) – polyurethane (PU) industrial chain from all over the country attended the meeting.

First of all, LV Guoyang, Secretary General of China Polyurethane Industry Association, and Liu Yi, chairman of Shandong Bluestar Dongda Co., Ltd., respectively delivered welcoming speeches to the meeting and extended a warm welcome to all experts, scholars, backbone and colleagues of the enterprise.

LV Guoyang, Secretary General of China Polyurethane Industry Association

Liu Yi, chairman of Shandong Bluestar Dongda Co., Ltd

Special report

On the morning of December 17, the meeting was presided over by Guo Hui, chief engineer and assistant general manager of Shandong Bluestar Dongda Co., Ltd.

Guo Hui, chief engineer and assistant general manager of Shandong Bluestar Dongda Co., Ltd

Li Jianbo, Deputy Secretary General of China Polyurethane Industry Association

Li Jianbo, Deputy Secretary General of China Polyurethane Industry Association, made a report entitled “impact of national safety and environmental protection policies on the development of po-ppg-pu industrial chain”.

Yu Chunmei, deputy chief engineer of PetroChina Jilin Chemical Engineering Co., Ltd

Yu Chunmei, deputy chief engineer of PetroChina Jilin Chemical Engineering Co., Ltd., made a keynote report entitled “analysis of propylene oxide industry development trend and investment opportunities”.

Ma Huiling, deputy general manager of Shandong Bluestar Dongda Co., Ltd

Ma Huiling, deputy general manager of Shandong Bluestar Dongda Co., Ltd., made a report entitled “journey and take-off of China’s polyether polyol industry”.

Dr. Feng Yanli, senior scientist of Dow chemistry

Dr. Feng Yanli, senior scientist of Dow chemistry, made a keynote report entitled “waterborne polyurethane technology and the application of Syntegra PUD in artificial leather”.

Xue Cong, chemical industry analyst of Guosen Securities

Xue Cong, a chemical industry analyst at Guosen Securities, made a keynote report entitled “the boom around C keeps rising and a hundred schools of thought contend for a variety of processes”.

容威聚氨酯有限公司采购部经理-袁启超.png)

Yuanqichao, purchasing manager of Wanhua chemical (Yantai) Rongwei Polyurethane Co., Ltd

Liu xianbo, R & D Manager of Wanhua Chemical Co., Ltd

Yuan Qichao, manager of procurement department of Wanhua chemical (Yantai) Rongwei Polyurethane Co., Ltd., and Liu xianbo, R & D Manager of Wanhua Chemical Co., Ltd., successively shared the theme of “development prospect of Po and polyether supply and demand”.

Xiao Jie, deputy general manager of Suzhou antway Valve Co., Ltd

Xiao Jie, deputy general manager of Suzhou antway Valve Co., Ltd., made a report entitled “selection and intelligent manufacturing of propylene industrial production units and tank farm emergency shut-off valves”.

On the afternoon of December 17, the meeting was presided over by Li Jian, executive vice president of Shandong Yinuowei new materials Co., Ltd.

Li Jian, executive vice president of Shandong Yinuowei New Material Co., Ltd

Lin min, professor level senior engineer of Sinopec Petrochemical Research Institute

Lin min, professor level senior engineer of Sinopec Petrochemical Research Institute, delivered a keynote report entitled “technical development and industrial application of propylene hydrogen peroxide to propylene oxide”.

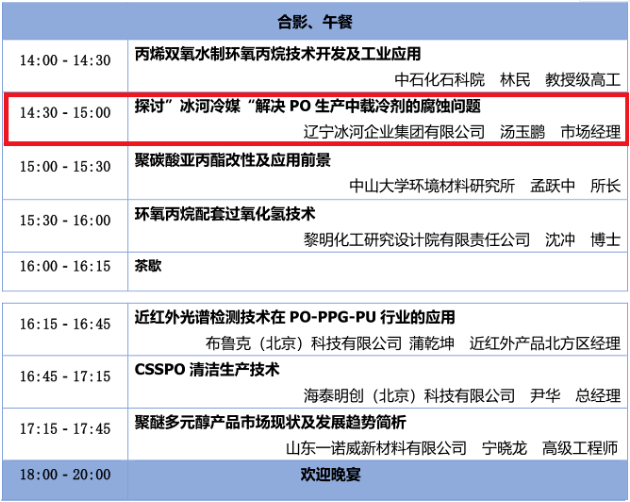

Tang Yupeng, marketing manager of Liaoning Glacier Enterprise Group Co., Ltd.

Tang Yupeng, marketing manager of Liaoning Glacier Enterprise Group Co., Ltd., discussed “Glacier coolant” to solve the corrosion problem of coolant in Po production.

Meng Yuezhong, director of the Institute of environmental materials, Sun Yat sen University

Meng Yuezhong, director of the Institute of environmental materials of Sun Yat sen University, made a report entitled “research progress of biodegradable carbon dioxide based semi aromatic copolymers”.

Dr. Shen Chong, liming chemical research and Design Institute Co., Ltd

Dr. Shen Chong of Liming chemical research and Design Institute Co., Ltd. made a keynote report entitled “propylene oxide supporting hydrogen peroxide technology”.

科技有限公司近红外产品北方区经理-蒲乾坤.png)

Pu Qiankun, manager of near infrared products North area of Brooke (Beijing) Technology Co., Ltd

Pu Qiankun, manager of near infrared products of Brooke (Beijing) Technology Co., Ltd., made a report entitled “Application of Brooke online near infrared spectroscopy detection technology in po-ppg-pu industry”.

科技有限公司-尹华-总经理.png)

Yin Hua, general manager of Haitai mingchuang (Beijing) Technology Co., Ltd.

Yin Hua, general manager of Haitai mingchuang (Beijing) Technology Co., Ltd., made a report entitled “csspo cleaner production technology”.

Ning Xiaolong, senior engineer of Shandong Yinuowei New Material Co., Ltd

Ning Xiaolong, senior engineer of Shandong Yinuowei new materials Co., Ltd., made a keynote report entitled “brief analysis of the market status and development trend of polyether polyols”.

On the morning of December 18, we continued our wonderful report under the chairmanship of Ji Xiangyang, general manager of Shanghai Qike fluorosilicone Material Co., Ltd.

Ji Xiangyang, general manager of Shanghai Qike fluorosilicone Material Co., Ltd

Jing Xiaodong, deputy general manager of Zibo Dexin federal Chemical Industry Co., Ltd

Jing Xiaodong, deputy general manager of Zibo Dexin federal Chemical Industry Co., Ltd., made a keynote report entitled “polyether polyol production technology and application of new products”.

Li Chengzhang, chief engineer of Linyi scorui polyurethane material Co., Ltd

Li Chengzhang, chief engineer of Linyi scorui polyurethane materials Co., Ltd., made a keynote report entitled “biomass polyols and their applications”.

Shanghai Qike fluorosilicone Material Co., Ltd. Ji Congqi

Ji Congqi of Shanghai Qike fluorosilicone Material Co., Ltd. made a thematic report entitled “Discussion on the quality improvement scheme of polyether polyols”.

Song Baoning, R & D Manager of Jiahua Chemical Co., Ltd., made a keynote report entitled “development of new polyether for hard foam & Application of new monomer in polyether synthesis”.

Chen Hailiang, senior engineer of Shandong Yinuowei Polyurethane Co., Ltd., made a keynote report entitled “application and development of polyurethane elastomer in medical field”.

Zheng Xingyuan, consulting manager of Tiantian chemical network, made a thematic report entitled “new crown year, PO / PPG supply and demand changes and price trend”.

On the afternoon of December 18, the delegates visited Dongyue economic development zone and Maqiao industrial park by bus.

Relying on the fluorosilicone new material cluster of Zibo Dongyue economic development zone and the new material industry cluster of Maqiao chemical industry park, this event will display the development achievements of the new material industry, promote multi-level information communication among government, enterprises, intelligence and association, and promote industrial technical cooperation by organizing a series of activities such as exhibition and exchange, project promotion, investment attraction and report meeting, press conference and exhibition of the new material industry; Attract a number of leading and base enterprises and strong chain, chain extension and chain supplement projects to further accelerate industrial development, improve quality, and promote the accelerated development and continuous upgrading of Zibo new chemical materials industrial cluster.

Meeting site

During the one-and-a-half day meeting, the experts made wonderful speeches. The delegates listened carefully. The chemical industry park and relevant equipment manufacturers interacted with the guests, seized the opportunity to enhance understanding and strive for cooperation opportunities.

Working principle and effect of evaporative condenser

Evaporative condenser is an efficient heat exchange equipment. It has the advantages of high heat transfer efficiency, energy saving, compact structure and convenient installation. The evaporation absorption capacity (latent heat) of equal quality water at room temperature is 115 times that of heat absorbed by water temperature rising by 5 ℃, which is the fundamental reason for water and power saving of evaporative condenser. It is widely used in large-scale chemical industry, medicine, steel, air conditioning, coal mine, nitrogen fertilizer and so on. It is also practiced in gas cooling, condensation and liquid cooling in ammonia synthesis, methanol synthesis, gas compression, distillation and waste heat recovery.

Working principle of evaporative condenser

The evaporation of some water is mainly used to take away the heat released by the condensation process of the gaseous refrigerant. The high-temperature gaseous refrigerant enters the coil from the refrigerant inlet at the upper part of the coil and exchanges heat with the spray water and air outside the coil. The gaseous refrigerant is gradually condensed into liquid and flows out from the refrigerant outlet at the lower part. The cooling water is sent to the spray system above the condensing coil by the water pump, and evenly sprayed on the outer surface of the condensing coil through the water distributor to form a thin water film. After the spray water and air absorb heat, the temperature rises, part of the water changes from liquid to gaseous, and a large amount of heat is taken away by the latent heat of evaporation. The rest of the water falls back to the lower collecting tank, and then sent to the spray system by the circulating water pump for recycling; The water droplets entrained in the air are blocked by the dehydrator and fall back to the water collection.

Structural characteristics of evaporative condenser

Countercurrent evaporative cooling: it is a kind of evaporative cooling that only uses the latent heat of water for heat exchange. It has large heat exchange area and is not easy to produce ice blockage and dirty blockage. It can operate in various environments, especially in the north. It has good effect and good effect without water in winter. The form of air inlet is countercurrent air inlet at the bottom, which alternates inversely with the spray water at the lower part to form saturated hot and humid air. The heat is discharged from the top fan. The water is recovered by the dehydrator with special structure and recycled in the water collecting tank. There is no heat exchange filler in the internal space, freeing up more space to increase the unit heat dissipation area of the coil. More compact structure and small land occupation. It is especially suitable for the situation that the outlet water temperature is close to the local wet bulb temperature.

Application fields of evaporative condenser

It is widely used in large-scale chemical industry, medicine, steel, air conditioning, coal mine, nitrogen fertilizer, gas cooling, condensation and liquid cooling in ammonia synthesis, methanol synthesis, gas compression, distillation and waste heat recovery.

In terms of structure, evaporative condenser is a combination of ordinary water-cooled condenser, cooling tower, water pump and pipeline connection of water system. It has the advantages of power saving, water saving and convenient installation. It has the characteristics of small floor area and convenient maintenance. However, there are essential differences in the principle of heat exchange. The water-cooled condenser uses the sensible heat of water to absorb the heat of refrigerant to achieve the purpose of refrigeration, while evaporative cooling uses the latent heat of water, that is, the evaporation of water at room temperature to absorb the heat to achieve the purpose of cooling. The heat absorbed by the evaporation of water of the same quality is 116 times that when the water temperature rises by 5 degrees. Therefore, when taking away the same heat, the water consumption of evaporative cooling is much lower than that of water-cooled condenser, which is also the fundamental reason for water and power saving of evaporative cooling.

Here he is! Here he is! CPHI world pharmaceutical raw materials China exhibition is coming to us!!!

Count the days. In two days, CPHI China 2020, the annual grand finale of the pharmaceutical industry, will open, welcoming more than 3000 exhibitors and more than 70000 online and offline visitors at home and abroad.

What is CPHI China?

CPHI China, the full name of the world pharmaceutical raw materials China exhibition, was introduced to China in 2001 and the 20th world pharmaceutical raw materials China exhibition will be held in 2020. It is a world-famous one-stop vertical trade and exchange event in the pharmaceutical industry. It closely follows the industrial policies at home and abroad, grasps the innovation trend in the industry, makes use of rich industrial resources, and provides professionals with services from pharmaceutical raw materials, contract customization, biopharmaceutical, pharmaceutical machinery The integrated solution from packaging materials to laboratory instruments will expand global contacts for domestic pharmaceutical enterprises. This exhibition will have 70000 professional visitors from more than 140 countries and regions at home and abroad.

Is it a little exciting to see here?

Has the scene of stars gathering and heroes gathering been depicted in your head?

Have you been unable to control the pace of departure and want to fly to Shanghai?

Good news for you – we’re here too!

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, the three major problems of traditional coolant “corroding equipment, low efficiency and polluting the environment” are solved, and the service life of refrigeration equipment is prolonged by more than twice.

The R & D center of the company was awarded by the provincial Ministry of science and technology to Liaoning engineering technology center. It has Liaoning liquid heat transfer medium laboratory and glacier heat transfer medium testing center, which can carry out authoritative testing on various physical and chemical indexes of ultra-low temperature heat transfer medium. Since 2000, it has won more than 30 awards, including more than 20 awards at or above the provincial level. It has successively obtained 14 national patents, including 11 invention patents and utility model patents.

If you want to know more about our partners, please remember that our booth number is e6e42. Please refer to the route below to enter area E6. After entering, you can find E42 and see us!

This time, the glacier coolant also prepared a turntable lottery for you. The mysterious prize is waving to you~

It’s time to show your luck!

2020 China PO-PPG-PU industrial chain high quality development forum is meeting you in Zibo

With the gradual improvement of refining and chemical integration, propane dehydrogenation and MTO capacity in China, propylene resources are becoming more and more abundant, providing sufficient raw materials for propylene oxide industry. New processes such as HPPO, CHP and POSM are becoming more and more mature, and new projects are increasing; As a large downstream chain of Po industry, PPG-PU industry will face many challenges in the future, such as technology optimization, quality upgrading and market development. The development of PO-PPG-PU industry chain is about to enter a new pattern.

In order to promote the high-quality development of PO-PPG-PU industrial chain and meet market challenges. Glacier refrigerant invites you to participate in the “2020 China PO-PPG-PU industrial chain high quality development forum” held by the polyol Professional Committee of China Polyurethane Industry Association and Beijing United Nations new material technology center in Zibo, Shandong Province from December 16 to 18, 2020.

Industry experts and industry elites gathered together to discuss hot issues in the industrial chain. Glacier coolant will make a technical report on the corrosion of metal equipment by coolant in PO-PPG-PU production process.

At the same time, the “2020 first Zibo Chemical new materials” four new “exhibition was held.

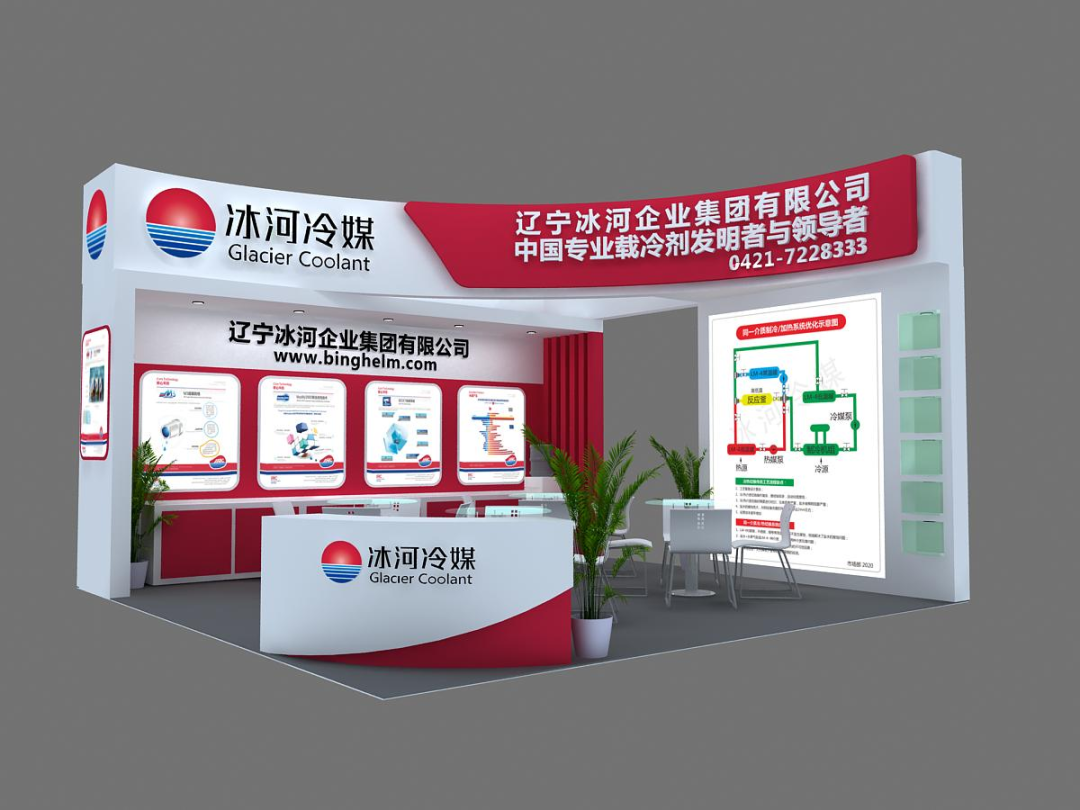

【Glacier Coolant】will be waiting for you at “Zibo Convention and Exhibition Center – booth a11”.

Our booth looks like this. Don’t go wrong!↑

LM series glacier coolant, the leading product of glacier coolant Technology Co., Ltd., is used in refrigeration fields such as pharmacy, chemical industry, refrigeration, HVAC and so on. The products have more than 30 models, and the application range is – 135 ℃ ~ 350 ℃, which can fully meet various needs of secondary refrigeration system.

LM series glacier coolant has the characteristics of wide temperature range, low viscosity, high thermal conductivity and large specific heat. Through m3 super film antirust technology and modify2000 composite modification technology, the three major problems of traditional coolant “corroding equipment, low efficiency and polluting the environment” are solved, and the service life of refrigeration equipment is prolonged by more than twice.

Picture (first on the left: Glacier coolant LM-4, second on the left: 25% saline, third on the left: 30% saline)

The company has 2000 + stable customers in the pharmaceutical industry, chemical industry, refrigeration industry, food industry, scientific research institutes and other fields. Professional R & D personnel, excellent sales team and perfect after-sales service, “Glacier coolant” is your high-quality partner!

The third 2020 Symposium on pharmaceutical and chemical process safety and safety production management was successfully held

On November 27, 2020, the third 2020 Symposium on process safety and safety production management of pharmaceutical and chemical industry, sponsored by the state of chemical industry and the pharmaceutical and chemical industry professional committee of China Chemical Enterprise Management Association, was successfully held in Jinan, Shandong Province.

Members of the delegation of our company, Wang Xinmiao from the sales department, Tang Yupeng and Zhang Meng from the marketing department attended the meeting

The background of this meeting is:

Due to the high risk, strict operation requirements and operation level of its production process and production technology, the probability of danger is quite large, which is related to the life safety of its employees and the vital interests of the enterprise. How to ensure safe production, how to control and reduce the risk coefficient, determine the risk degree of reaction process, so as to improve the design of safety facilities, improve risk control measures, improve the production safety of pharmaceutical and chemical enterprises, carry out safe production management, and ensure the development and operation of enterprises.

The seminar was taught by 13 teachers, 8 enterprises placed booths at the meeting site, and nearly 200 people attended the meeting.

On November 27, pan Guojun, general manager of Jinan aikesbote Safety Technology Consulting Co., Ltd., gave a lecture on chemical safety leadership and execution

Chen Wanghua, professor and doctoral supervisor of the Department of safety engineering, School of chemical engineering, Nanjing University of technology, gave a lecture on thermal risk problems in chemical process and their countermeasures

Wang Jianna, deputy general manager of Shandong Runbo Biotechnology Co., Ltd. and director of process safety laboratory, lectured on the early combination of process, engineering, safety and reaction heat research

Wu Zhanjun of Shanghai Yurui Management Consulting Co., Ltd. lectured on Cause Analysis and preventive measures of common electrical accidents

During the tea break, everyone went to each booth for warm exchanges

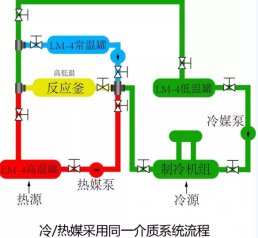

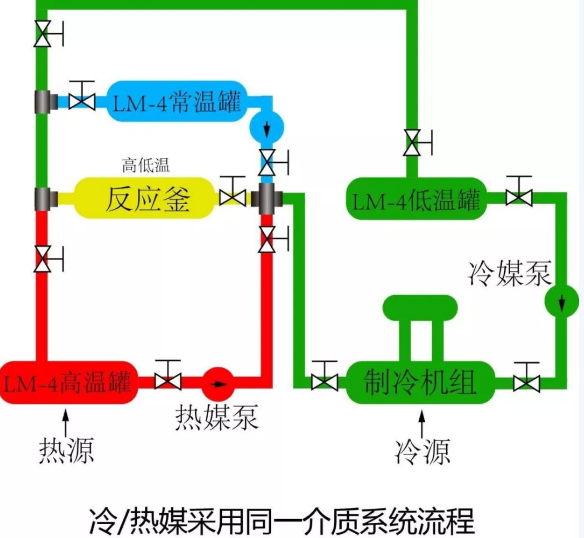

Glacier coolant Technology Co., Ltd. has in-depth cooperation with pharmaceutical, chemical, refrigeration and other industries. In view of the defects of the conventional cold and heat switching process, the process is optimized to LM-4 glacier coolant heat exchange control system as shown in the figure.

Advantages of LM-4 glacier coolant heat exchange control system:

(1)More simplified equipment

If the production process requires high, medium and low working temperatures, the new system only needs to be equipped with one heating device, one closed cooling water tower and one refrigeration unit.

(2)Simplified piping system

Because the systems are closed systems, the design and installation of pipeline system are more simplified. There is no need to install steam traps or compressed air pipes for hot equipment.

(3)Easier operation

In the same equipment, when three different temperature media are switched according to the process requirements, it is only necessary to switch the valve as needed. There is no need to worry about the cross flow of different types of heat exchange media. This is also a problem that the heat exchange system is worried about before optimization.

4)The amount of maintenance is greatly reduced

Because LM-4 glacier coolant has good rust resistance and adopts LM-4 glacier coolant for both cooling and heating media, it can prolong the service life of pipelines and equipment. If you do better in valve selection and installation process, the phenomenon of running, dripping and leakage that has plagued the pharmaceutical and chemical industries will be eliminated, and the on-site management work can also be done better.

(5)Equipment investment and operation cost can be reduced

Since the heat exchange systems with the same medium at three temperatures are closed systems, the water treatment system of steam boiler, circulating water tank in medium temperature system, salt water tank and chemical salt tank can be omitted in the initial construction. At the same time, the daily operation also eliminates the operation and operation costs such as the treatment and renewal of water treatment resin, regular desilting of circulating water tank and salt water replenishment.

After the tea break, Hu Xiaoyong, director of Shanghai Lanbao Environmental Protection Technology Co., Ltd., shared the key points of VOCs governance under the new situation

Tang bin, executive director of Beijing bianda Technology Co., Ltd., gave a lecture on scene based dynamic risk management and control technology of chemical process

Wei Chuan, general manager of production safety software center of Zhejiang zhongkong Technology Co., Ltd., gave a lecture on the overall solution of digital application of production safety

Deng Zhonghao, product director of METTLER TOLEDO RC1, gave a lecture on the application of RC1 in reaction calorimetry and process safety assessment

Ma Junhai, senior engineer and regional business director of Corning Reactor Technology Co., Ltd., gave a lecture on the intrinsic safety solution of micro reaction technology in the application of pharmaceutical and chemical industry

At about 18 PM, the scene of Corning intrinsic safety – dinner exchange was very lively.

Everyone gathered together and enjoyed the live performance brought by the band and local delicacies.

The tense and exciting lucky draw pushed the atmosphere of the dinner to a climax.

Finally, the banquet ended with laughter.

On November 28, you Xizhong, a production safety expert and senior engineer of Jinan Anke Safety Technology Center Co., Ltd. in Shandong Province, gave a lecture on root cause analysis and Countermeasures of accidents in pharmaceutical and chemical industry

Hu Dengping, manager of dekaida consulting Asia Pacific process safety laboratory, lectured on safety design strategy and safety management system of fine chemical enterprises

Su Zhenyu, founder of Shanghai yunenthalpy Technology Co., Ltd., gave a lecture on how to eliminate fire and explosion accidents in fine chemical enterprises

After the conclusion of the meeting, Shandong Runbo Biotechnology Co., Ltd. invited you to visit the process safety laboratory.

At about 15 pm, the meeting came to a successful conclusion.